I-10 CSLM 5.5 to Atchafalya Floodway

I-10 CSLM 5.5 to Atchafalya Floodway

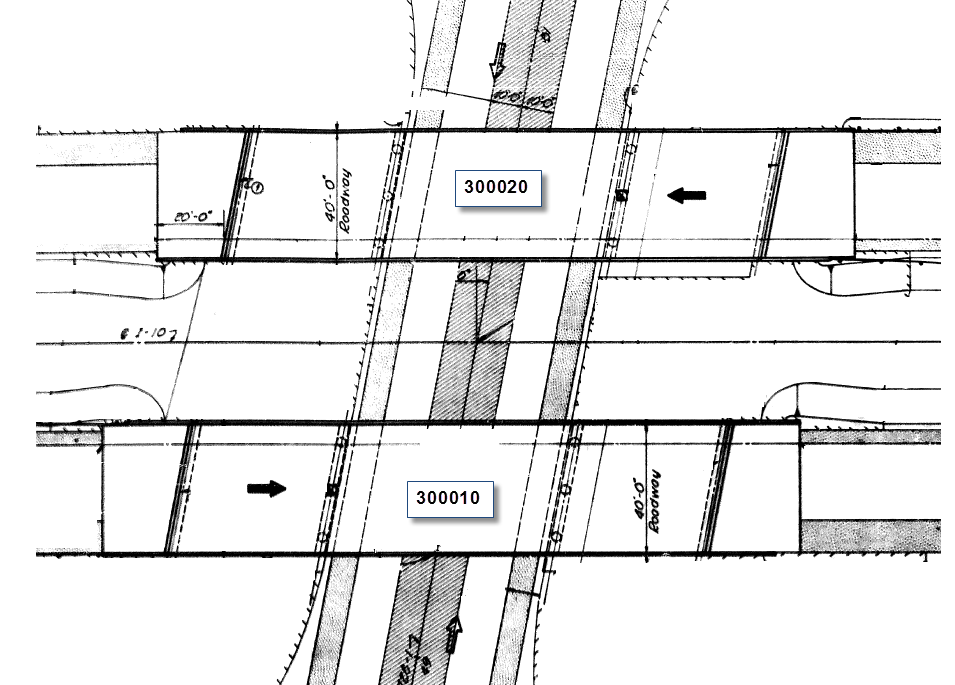

Eight (8) bridges along I-10 interstate from CSLM 5.5 to Atchafalaya Floodway were evaluated as part of Stage 0 Study (feasibility analysis). The total bridges lengths varied from 180 ft. to 1752 ft. Superstructure comprises precast prestressed concrete (PPC) girders, steel I beams, and steel plate girders. The substructure comprises reinforced concrete (RC) hammerheads, RC column bents, and RC/PPC pile bents. The study included developing design alternatives for the widening and rehabilitation of the existing bridges.

SDR tasks included: compiling and reviewing of existing documents; in-depth inspection; structural evaluation and load rating of existing bridges; design of rehabilitation of existing bridges, and design of widening. SDR study concluded that selective intervention and widening are more feasible and more economic than replacement, while maintaining the structural performance and integrity.

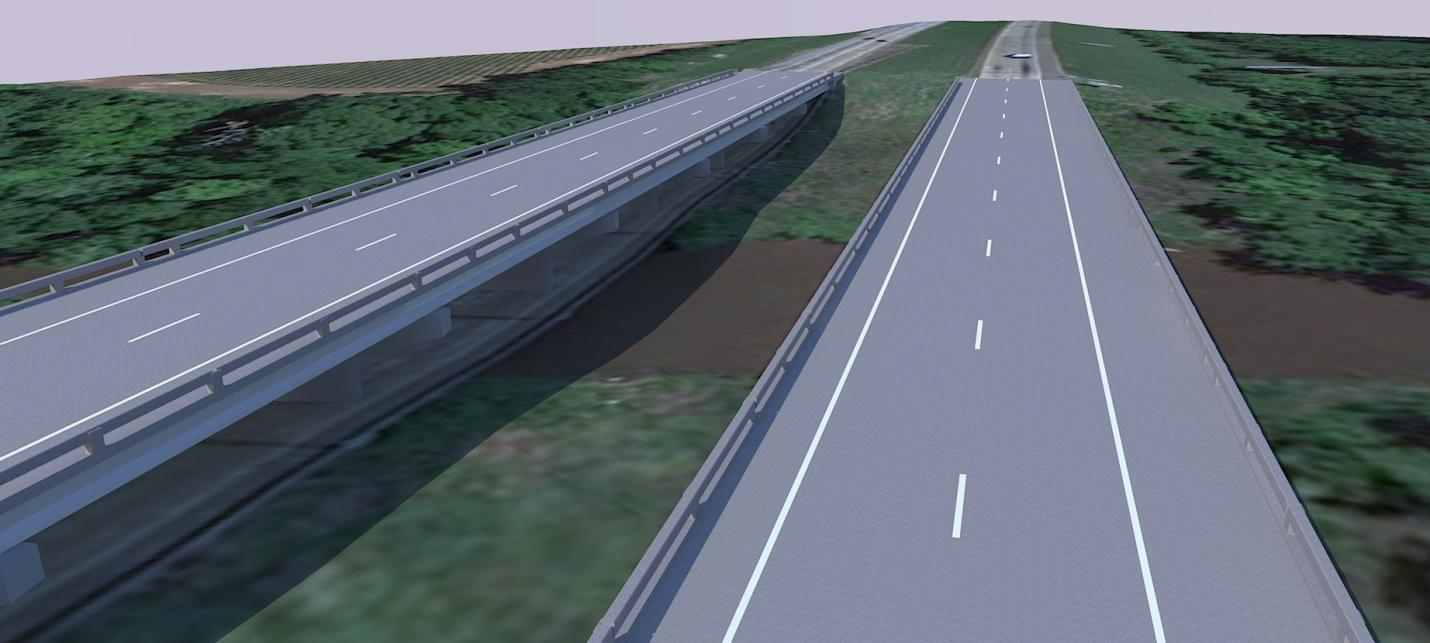

I-10 Lafayette Parish Line to CSLM 5.5

I-10 Lafayette Parish Line to CSLM 5.5

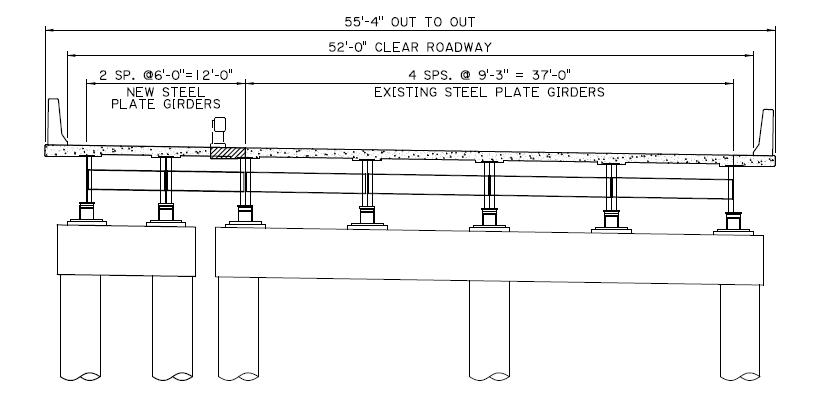

Six (6) bridges along I-10 interstate from Lafayette Parish line to CSLM 5.5 were evaluated as part of Stage 0 Study (feasibility analysis). The total bridges lengths varied from 198 ft. to 1275 ft. Superstructure comprises precast prestressed concrete (PPC) girders, steel I beams, and steel plate girders. The substructure comprises reinforced concrete (RC) hammerheads, RC column bents, and RC/PPC pile bents. The study included developing design alternatives for the widening and rehabilitation of the existing bridges.

SDR tasks included: compiling and reviewing of existing documents; in-depth inspection; structural evaluation and load rating of existing bridges; design of rehabilitation of existing bridges, and design of widening. SDR study concluded that selective intervention and widening are more feasible and more economic than replacement, while maintaining the structural performance and integrity.

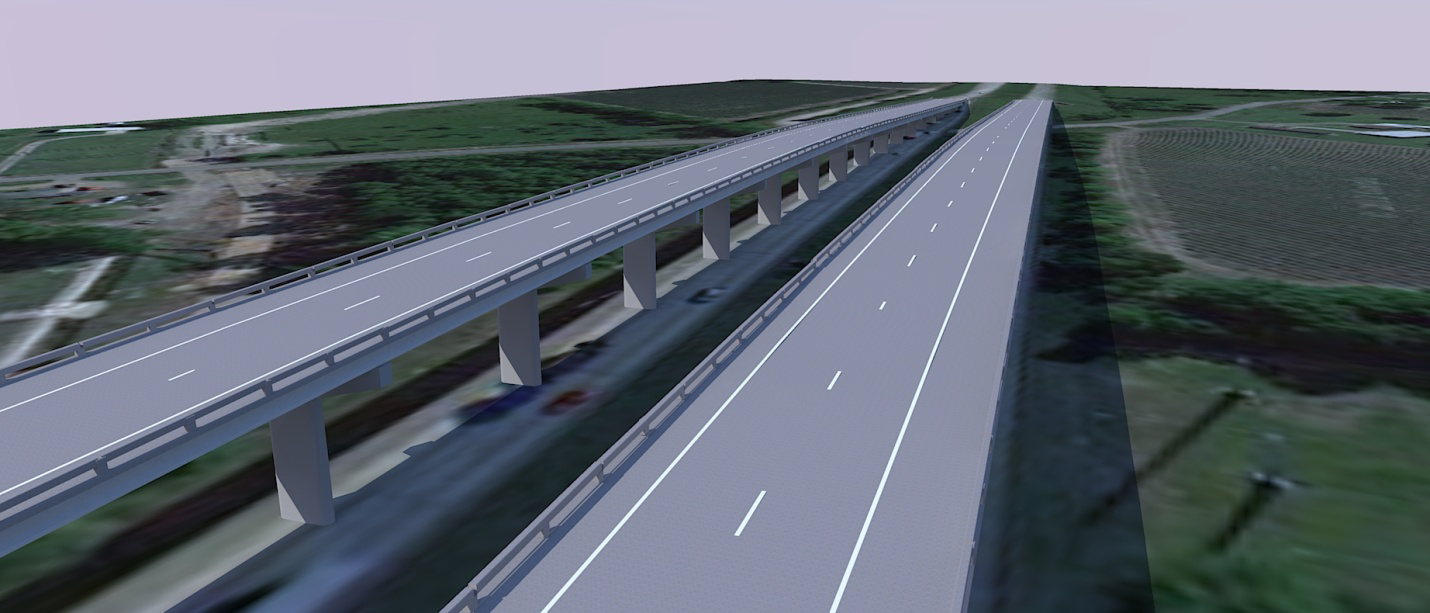

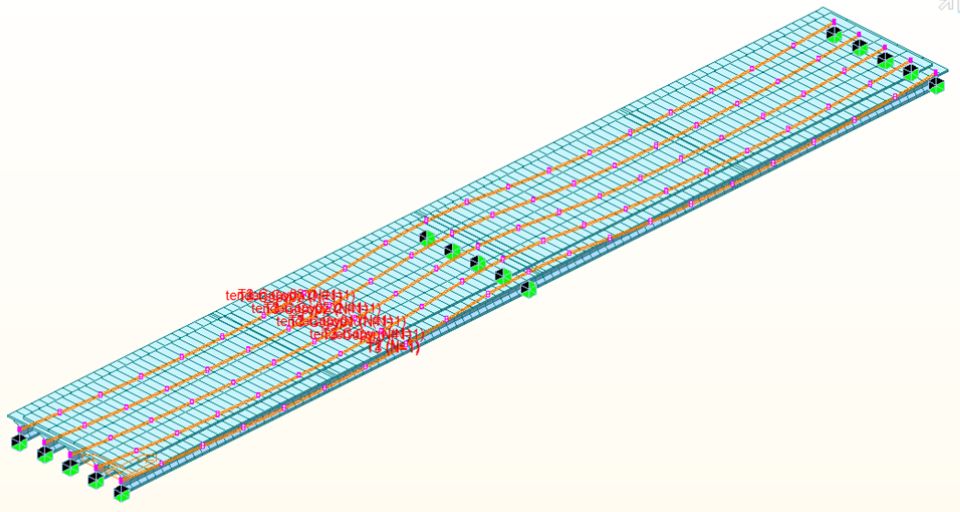

I-10 E Widening JCT. I-49 to St. Martin Parish Line

I-10 E Widening JCT. I-49 to St. Martin Parish Line

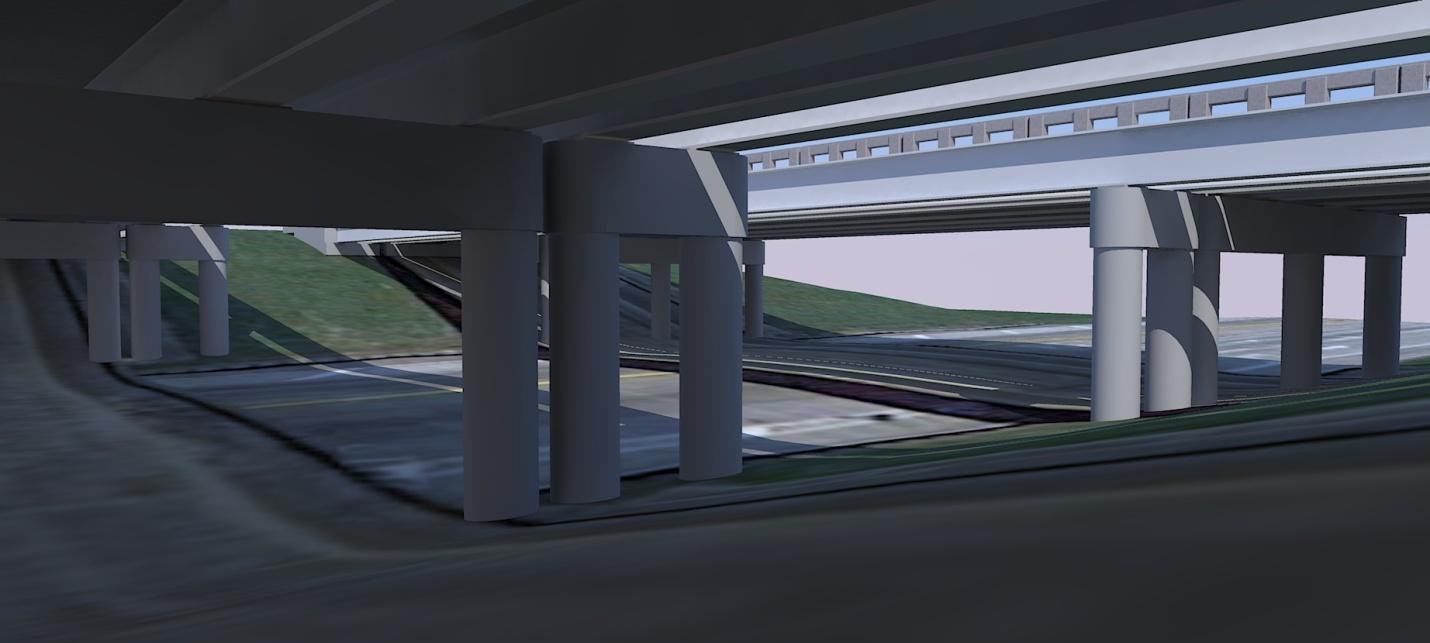

Eight (8) bridges along I-10 interstate from I-49 junction to St. Martin Parish line were evaluated as part of Stage 0 Study (feasibility analysis). The total bridges lengths varied from 138 ft. to 1365 ft. Superstructure comprises precast prestressed concrete (PPC) girders, steel I beams, and steel plate girders. The substructure comprises reinforced concrete (RC) hammerheads, RC column bents, and RC/PPC pile bents. The study included developing design alternatives for the widening and rehabilitation of the existing bridges.

SDR tasks included: compiling and reviewing of existing documents; in-depth inspection; structural evaluation and load rating of existing bridges; design of rehabilitation of existing bridges, and design of widening. SDR study concluded that selective intervention and widening are more feasible and more economic than replacement, while maintaining the structural performance and integrity.

Load Testing & Evaluation of Two Swing Span Bridges

Load Testing & Evaluation of Two Swing Span Bridges

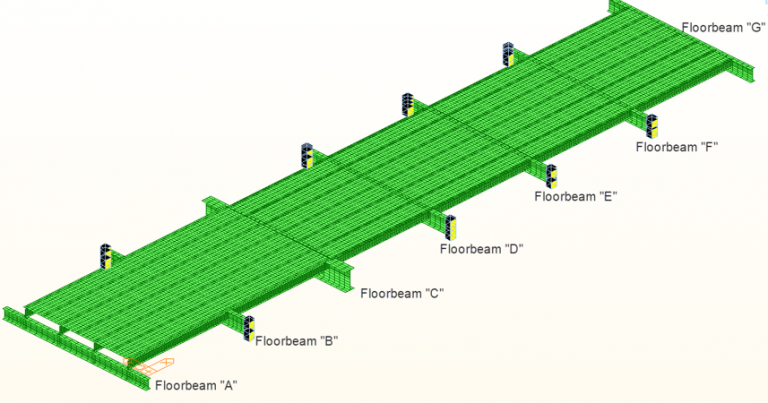

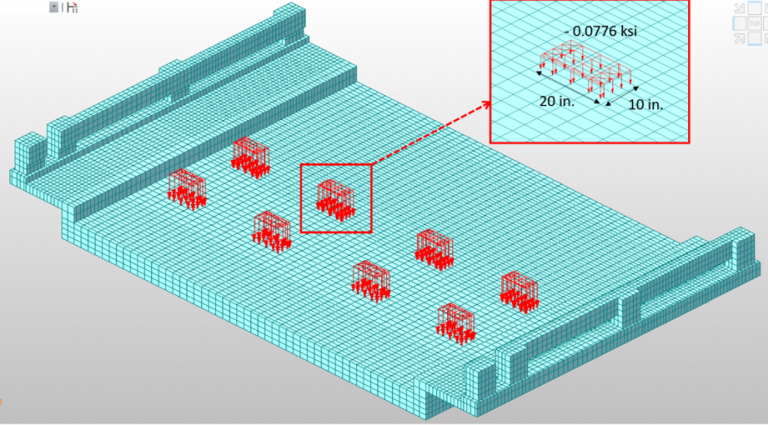

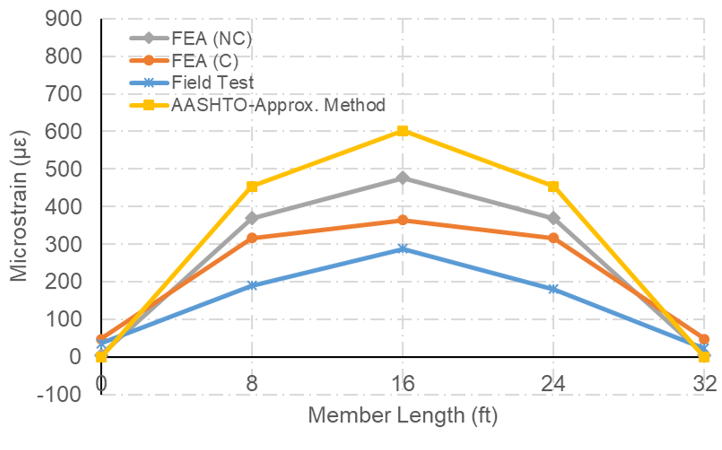

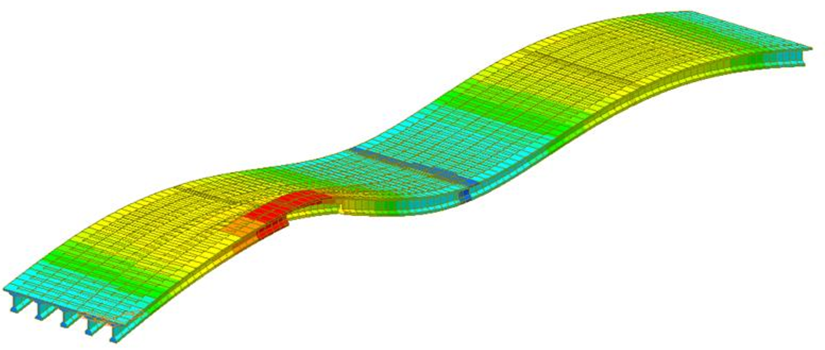

SDR was tasked to structurally evaluate two swing span bridges through load testing coupled with Finite Element Analysis (FEA) with the aim of removing the current load posting. The tested controlling spans comprised steel plate girder sowing span and CIP concrete slab spans. Test results revealed that, the actual performance of the test bridges is more favorable than what is estimated by design codes. Load rating of the controlling spans was revised considering test findings and FEA results, which resulted in removing the posting weight.

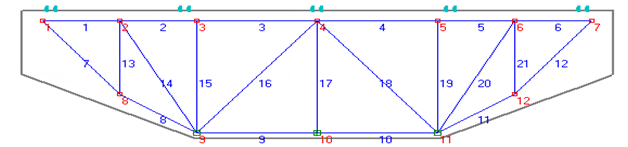

Load Testing & Evaluation of Five Fixed and Movable Bridges

Load Testing & Evaluation of Five Fixed and Movable Bridges

SDR was tasked to evaluate five bridges located along Louisiana State Highway 82 through load testing coupled with Finite Element Analysis (FEA) with the aim of removing the current load posting. The tested controlling spans comprised low truss swing spans; plate girder swing spans; steel I-beam approach spans; CIP concrete slab approach spans; and precast concrete slab spans. Test results revealed that, the actual performance of the test bridges is more favorable than what is estimated by design codes. Load rating of the controlling spans was revised considering test findings and FEA results, which resulted in removing the posting weight.

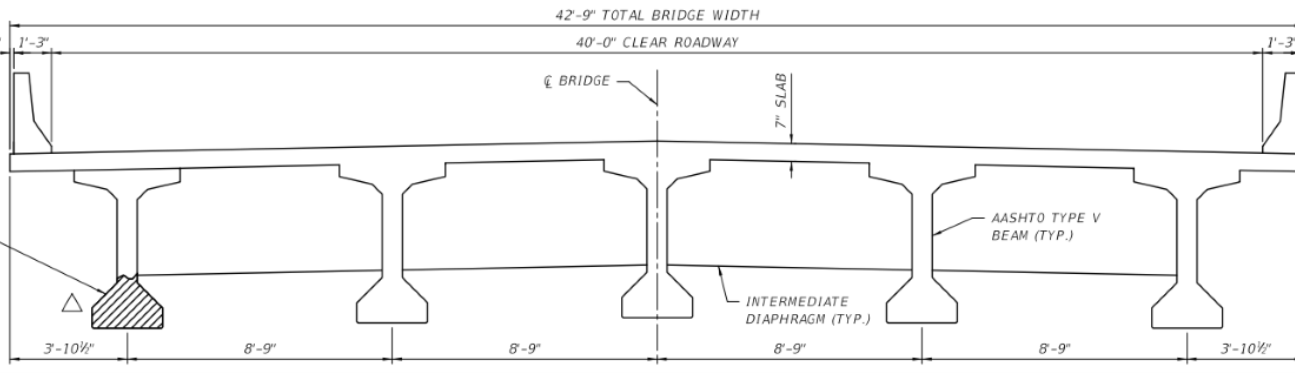

PROCTOR ROAD OVER I-75 BRIDGE

PROCTOR ROAD OVER I-75 BRIDGE

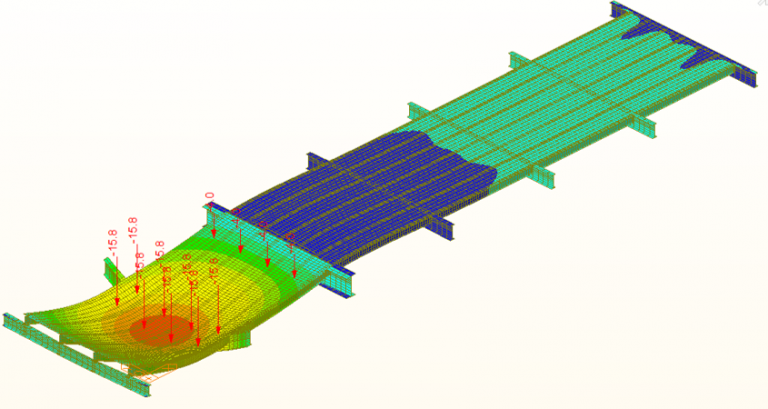

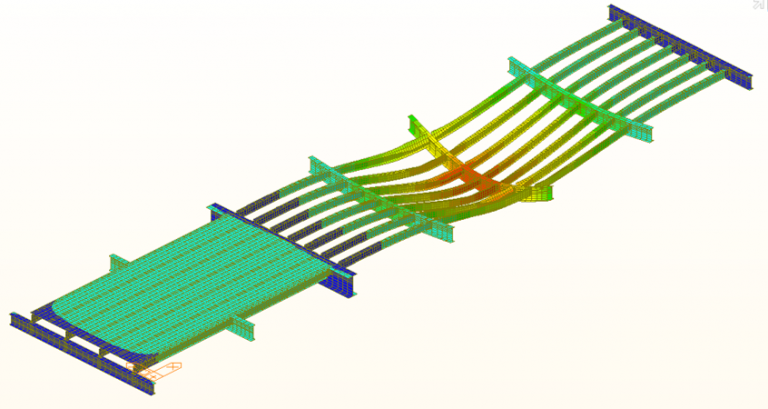

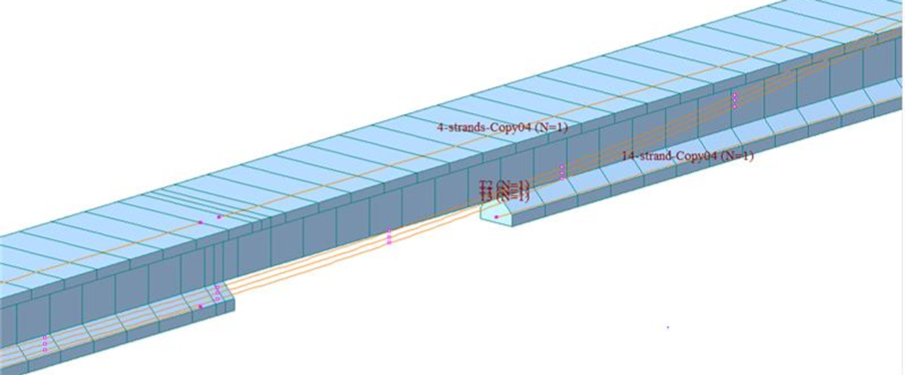

Proctor Road over I-75 in Sarasota, Florida is two continuous spans with a total bridge length of 282 ft. Superstructure comprises five AASHTO Type-V beams. Each beam span consists of two precast prestressed concrete (PPC) segments of 69 ft. long, connected using 1.5 ft. wide cast-in-place (CIP) closure pours at midspan. The two spans are made continuous using a similar 1.5 ft. wide CIP closure pour. Continuous post-tension (PT) over the two spans is provided by three draped tendons that are raised up at the intermediate bent.

The bridge was impacted by over-height truck causing damage to the exterior beam of span 1 in the form of partial section loss and rupture of prestressing strands with no damage to the PT tendons. Refined analysis was carried out to determine the feasibility of repair, and repair procedure. Further, the refined analysis was used to load rate the bridge after repair. The utilized repair procedure allowed for I-75 to remain open with partial lane closure overnight.

US 71 Market Street

US 71 Market Street

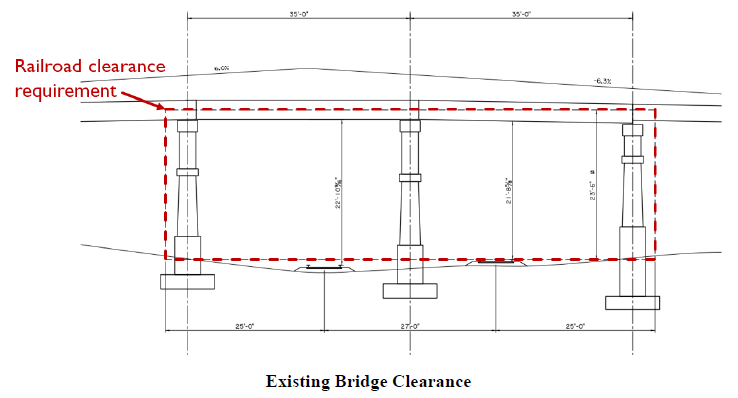

US 71-LA 1 bridge over ICG railroad was built in 1940 in downtown Shreveport, LA. Consisting of a two-bridge structure, each having 15 steel beam spans, 7 reinforced concrete spans, and reinforced concrete approach spans. The bridge covers a length of 850’ and a width of 20’. The US 71-LA 1 bridge carries or crosses multiple modes of transportation, while providing two 5’-11 ½” sidewalks and crossing two railroad tracks.

LA DOTD had posted the bridge for a speed limit of 25 MPH and posted load limits of 20T-35T. Based on further concerns LA DOTD assigned SDR with the task of performing a feasibility study on the twin two-lane bridge. SDR performed a thorough document review, hands-on inspection, and surveying to assess the conditions of the bridge. SDR field inspections indicated that the physical condition of the structure ranged from “fair” to “critical,” depending on their location.

Based on the structure’s old age, displacement, and severe exiting conditions, SDR proposed replacement of both structures and provided two alternate designs. One alternative utilized precast-prestressed concrete to satisfy the railroad’s minimum vertical and horizontal clearance. A second proposed alternative utilized a combination of precast-prestressed concrete girders and heavy, shallow rolled beams to meet railroad clearances. In both cases, span lengths from 80’ to 90’ were recommended to achieve maximum efficiency and to avoid interference with existing bridge foundations.

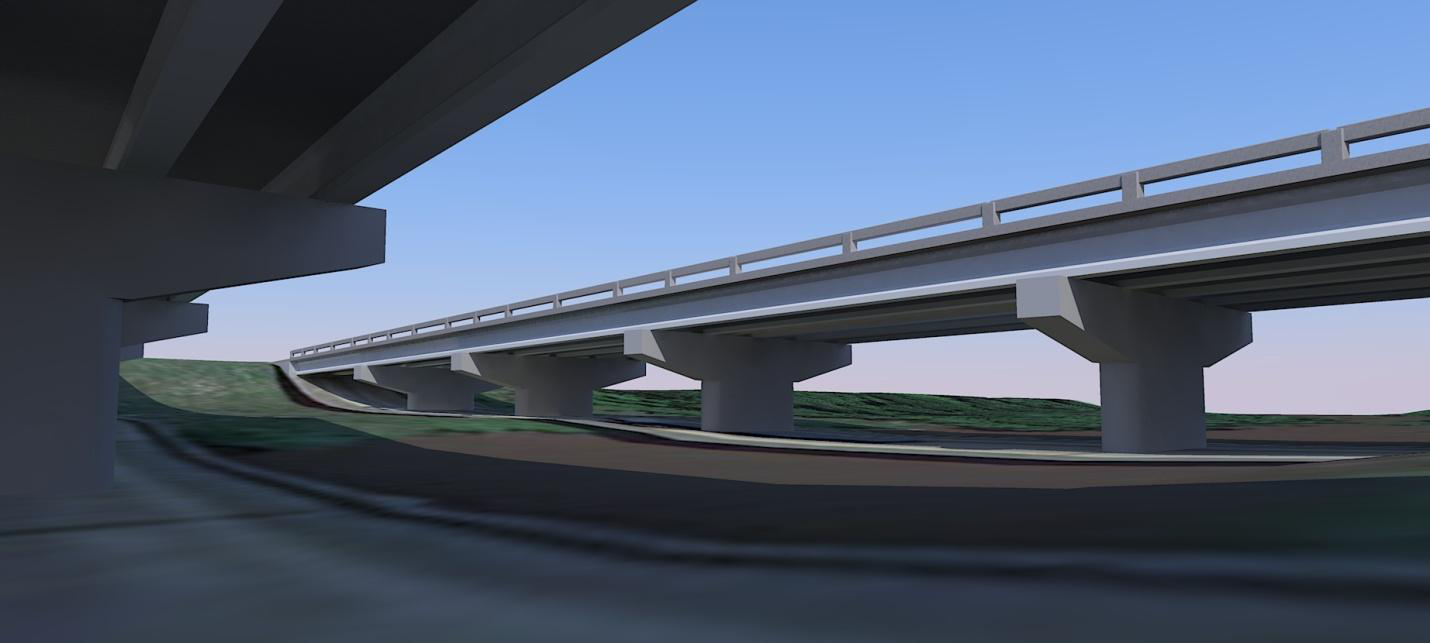

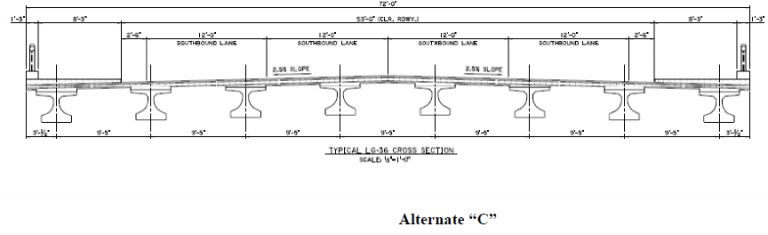

US-90 MACARTHUR DRIVE INTERCHANGE PHASE Phase II

US-90 MACARTHUR DRIVE INTERCHANGE PHASE II

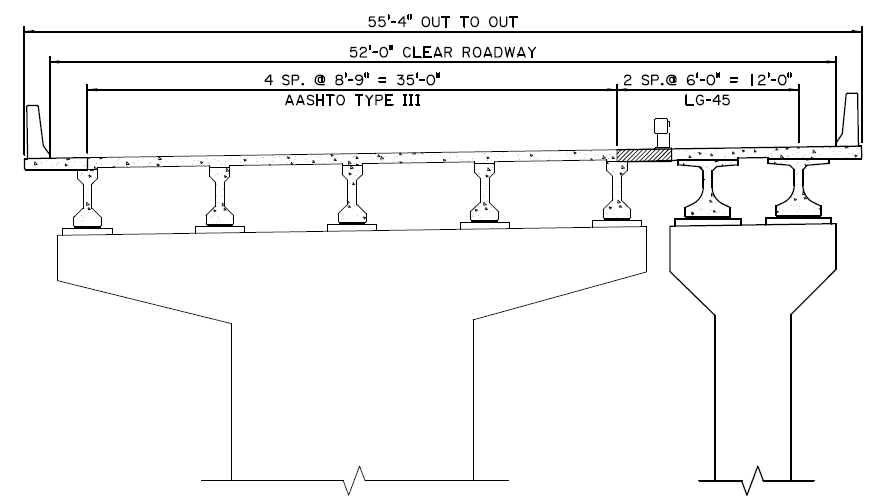

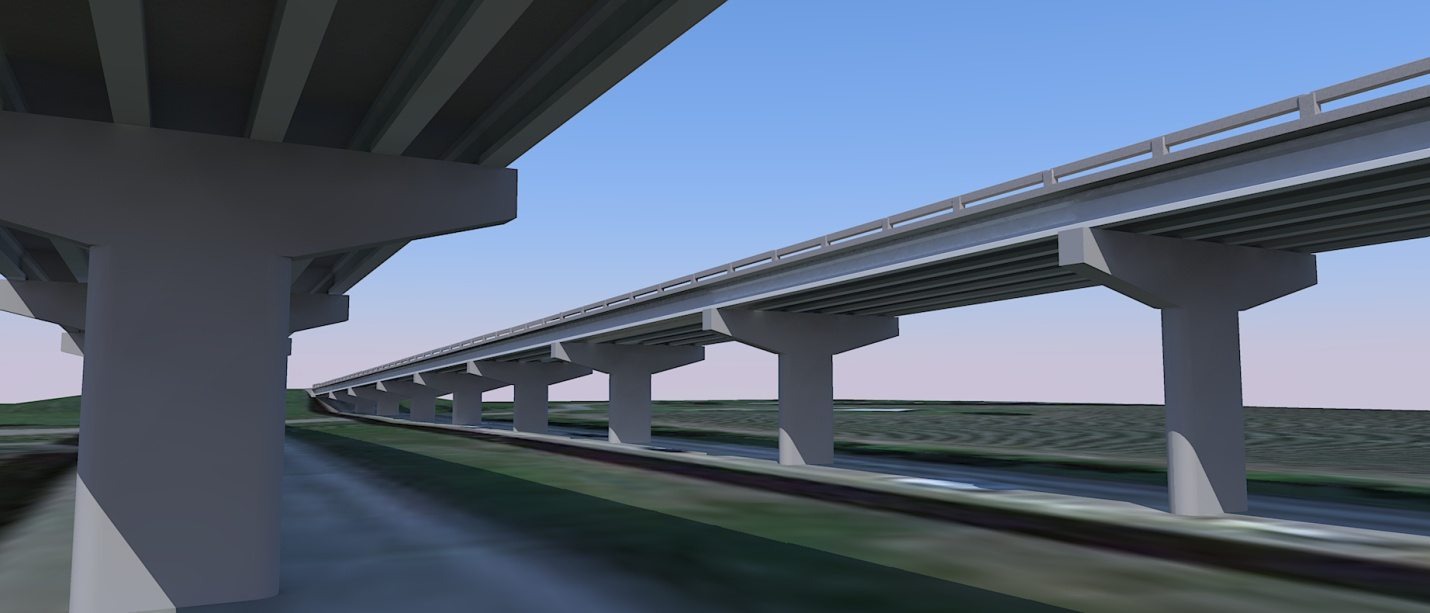

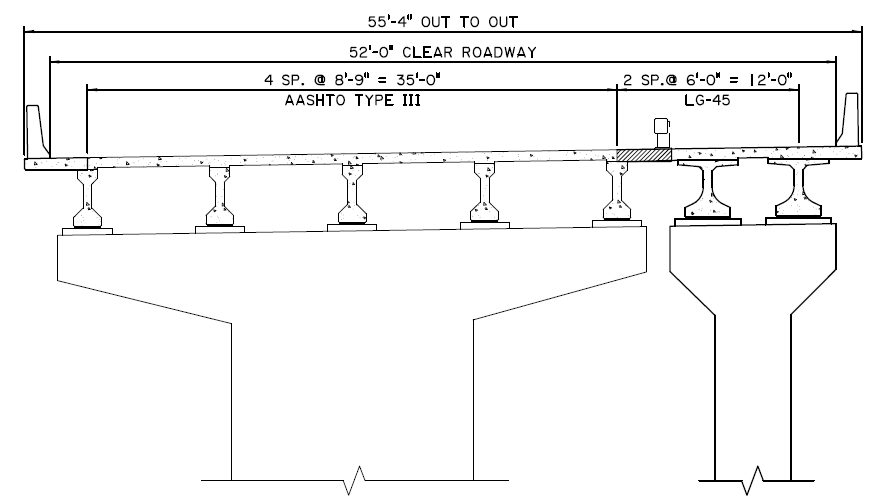

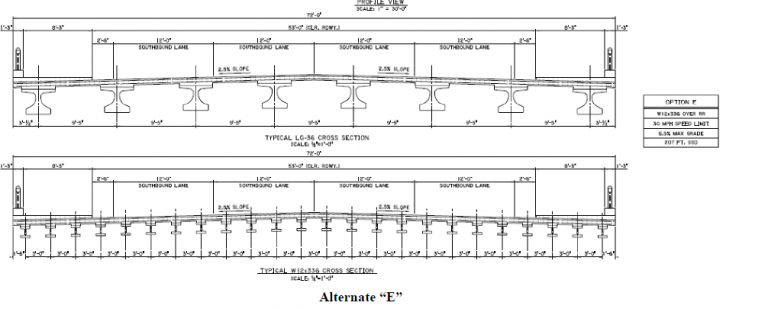

Constructed in the late 1950s, the Westbank Expressway is a six-lane urban, divided and elevated freeway. The elevated section extends from Westwood Drive in Marrero, Louisiana, to the Crescent City Connection Bridge across the Mississippi River, connecting the Westbank communities of Jefferson Parish with downtown New Orleans, Louisiana. Each structure of the elevated expressway includes three 12’ travel lanes, a 6’ interior shoulder, and a 10’ exterior shoulder. The bridges consist of trapezoidal concrete girders supporting a 7½”-thick concrete slab. The superstructure is supported on concrete single pier columns with pile-supported footings. The elevated freeway is supplemented by a six-lane divided service road system at ground level, running parallel to and outside of the twin elevated bridge structures, with ramp connections to major arterial cross streets at intervals of 0.7 to 0.9 miles throughout its length of nearly six miles.

SDR was tasked with providing access ramps from the service roads to the elevated freeway to and from the east and to reduce the distance between successive westbound off-ramps and eastbound on-ramps. SDR designed 22-spans of off-ramp and 24-spans of on-ramp. The design consisted of complex structural elements: precast-prestressed LU-girders and LG-girders, inverted T-cap beams, complex columns, and foundations. SDR also provided precise construction sequence, instructing the removal of existing structures to accommodate the new structure.

CR 514 Bridge Over I-75

CR 514 Bridge Over I-75

Repair of CR 514 Bridge over I-75 in Sumterville, Florida was completed by SDR. The bridge was struck by an over-height truck, causing severe damage to the exterior prestressed concrete girders, including rupture of several prestressing strands.

Before SDR’s involvement, it was determined to replace the girder. SDR was tasked to assess the damage and its impact on the structural integrity of the girders using its in-house developed damage assessment tools, design of the repair, and develop repair details. Repair of the girders included splicing of ruptured prestressing strands, correcting alignment and rotation of the bottom flange, restoring the concrete section, substituting ruptured stirrups using Near-Surface-Mounted technique, and applying externally bonded CFRP to confine the restored section and to provide redundancy to the shear strength. These repair methods allowed I-75 to remain open during construction.