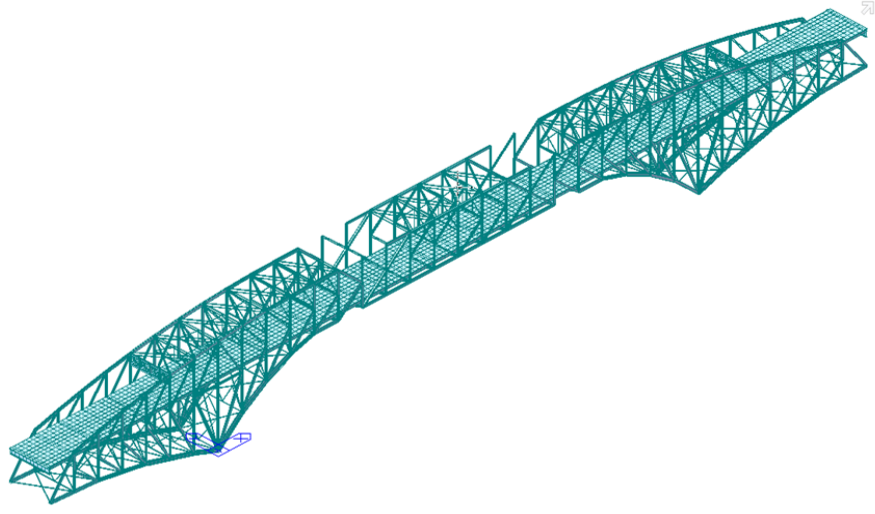

I-10 OVER CALCASIEU RIVER BRIDGE (LAKE CHARLES BRIDGE)

The I-10 bridge over Calcasieu River is a steel truss cantilever bridge, opened in 1952 in Lake Charles, LA. The bridge includes a steel main truss, four steel deck trusses, and ninety approach spans. The approach spans are comprised of steel girder spans and fracture critical spans (two-girder system with floor beams and stringers). The total bridge covers an approximate length of 6,617 ft. and a width of 62.67 ft.

The major scope of work included inspecting the entire bridge, determining the affect of section losses and deficiencies on load rating, building the 3-D finite element model for the truss spans using LUSAS, rating the truss members and gusset plates, load rating the approach spans using Virtis, load rating the substructure using RC-Pier, spreadsheets, and writing the final evaluation report with repair recommendations.