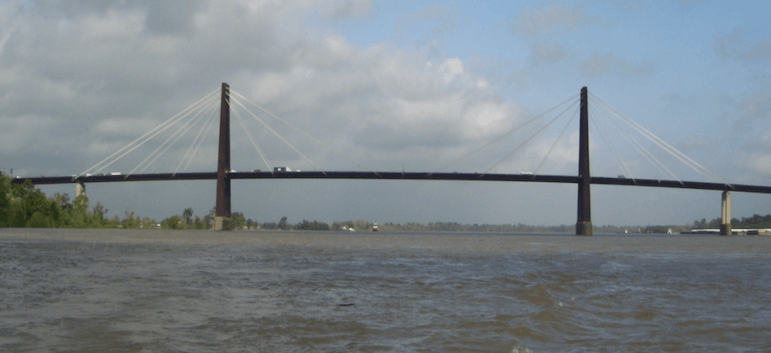

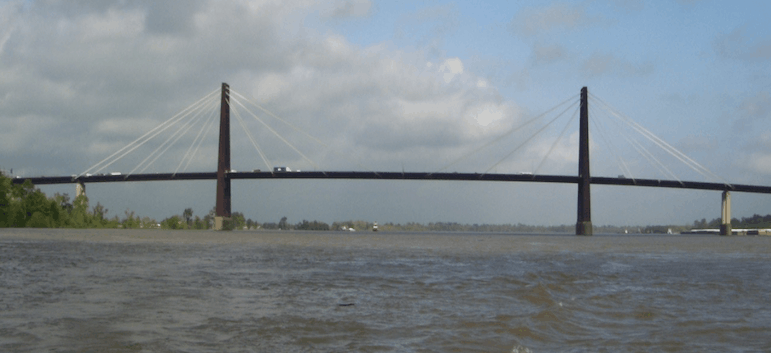

BAYOU LAFOURCHE BRIDGE TESTING

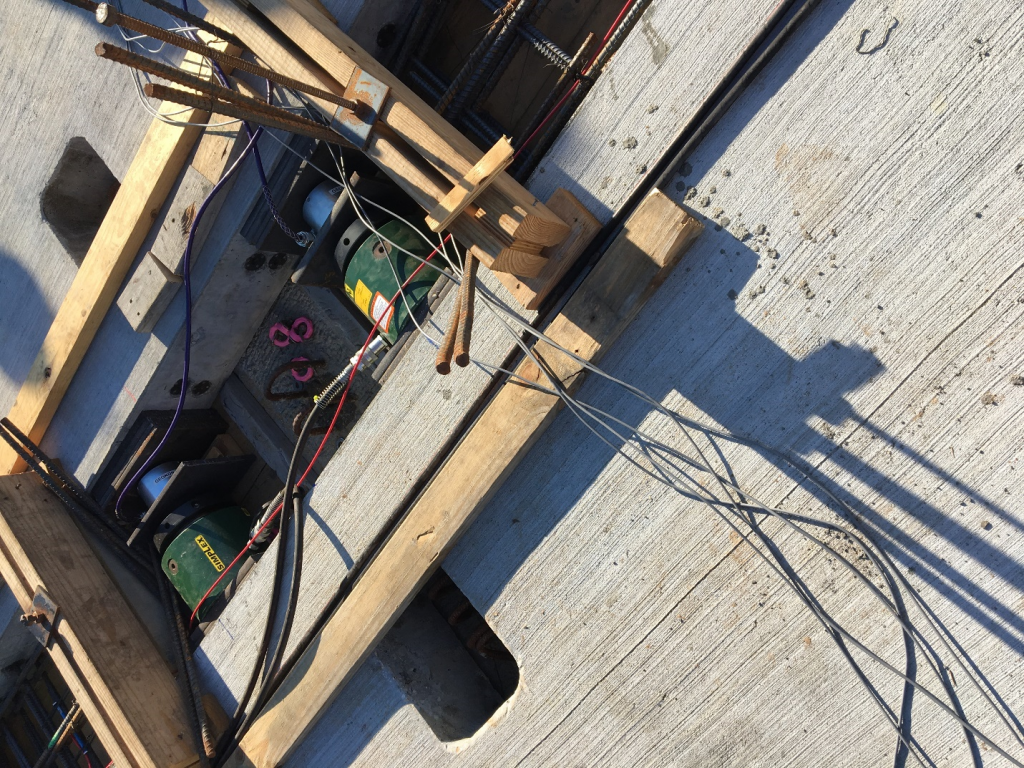

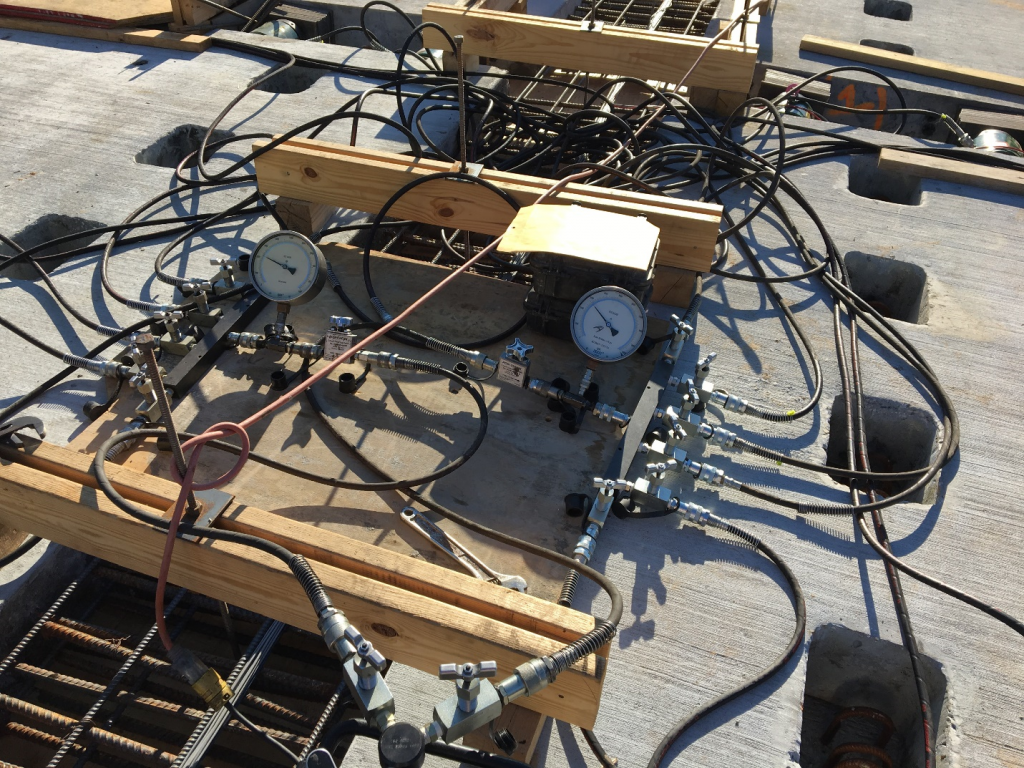

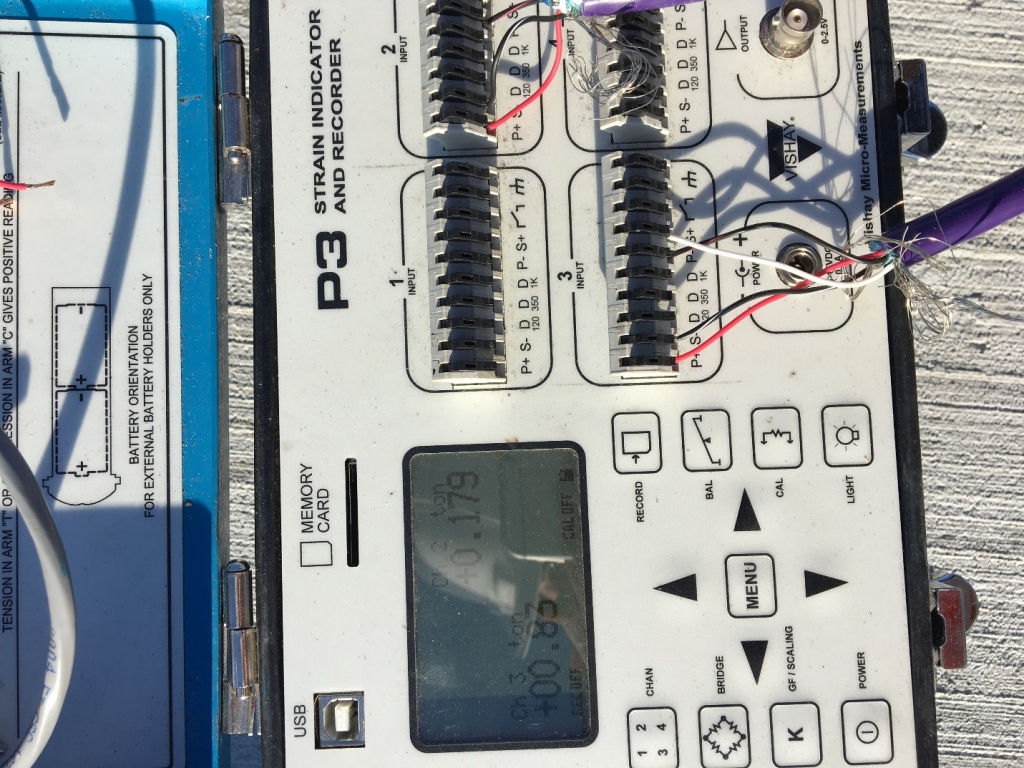

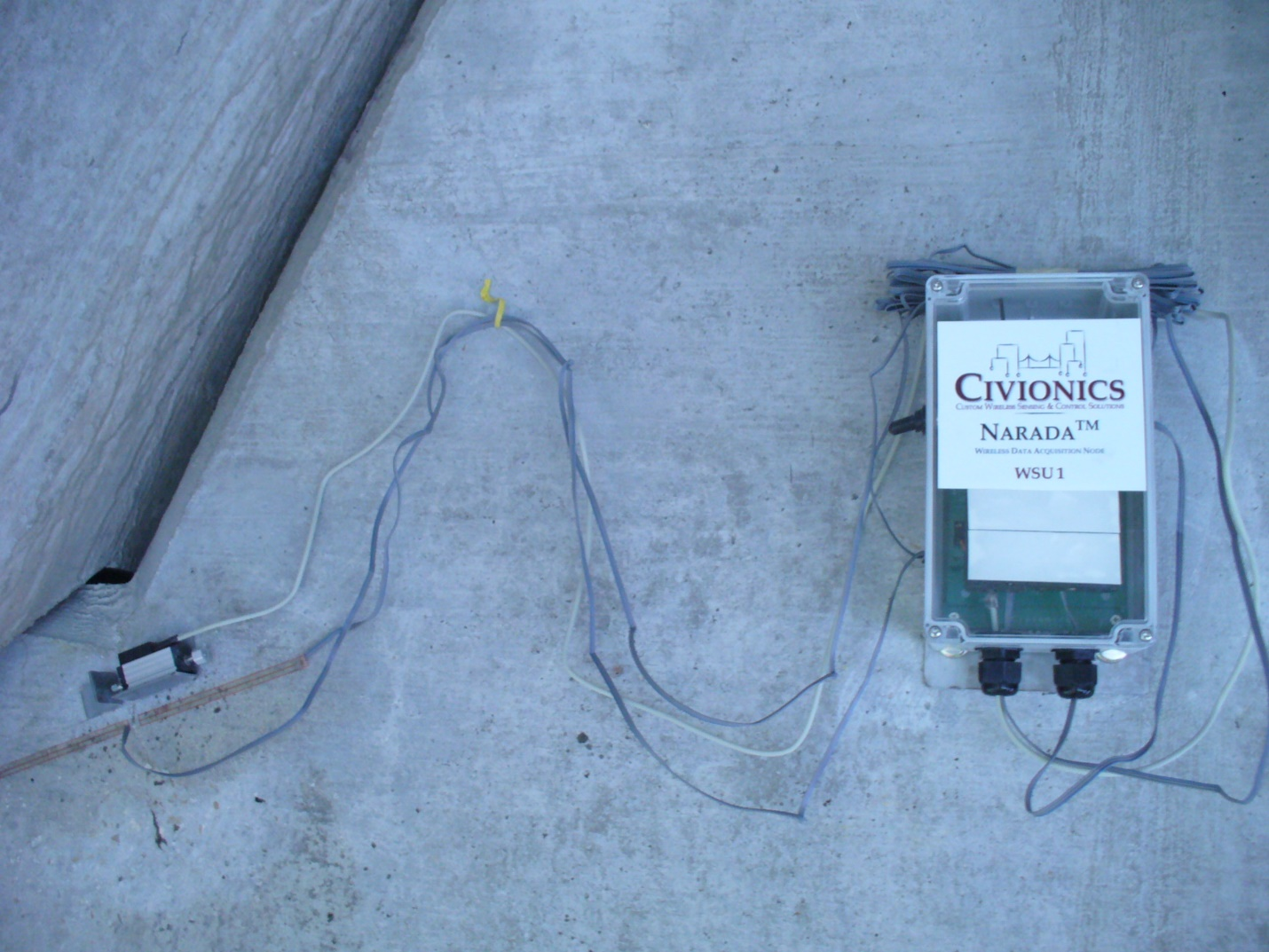

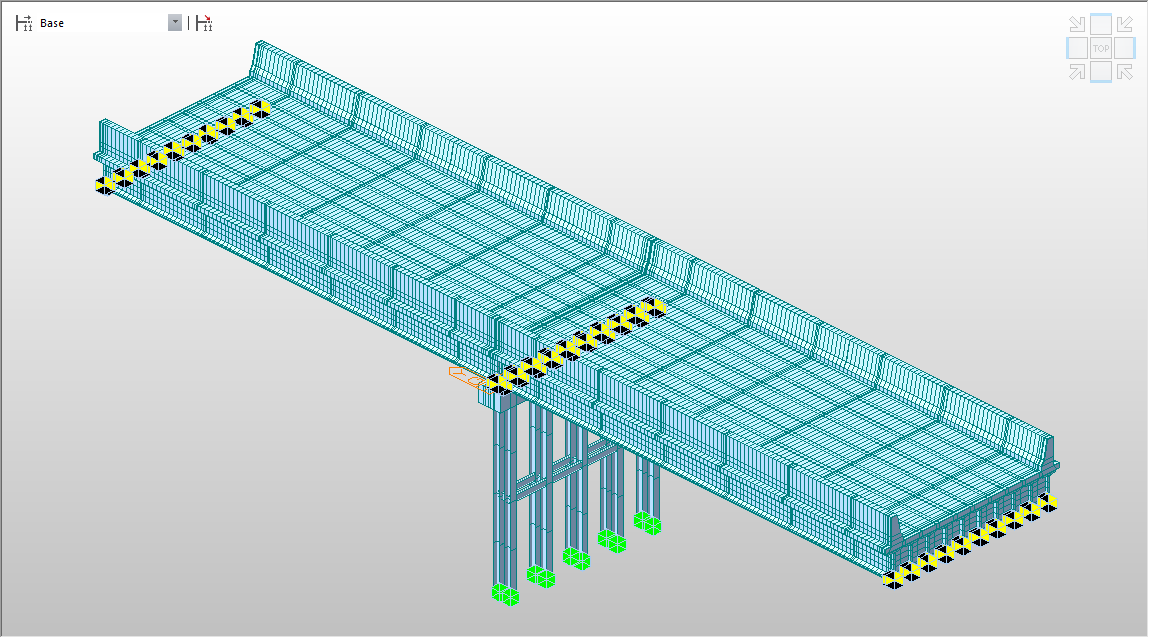

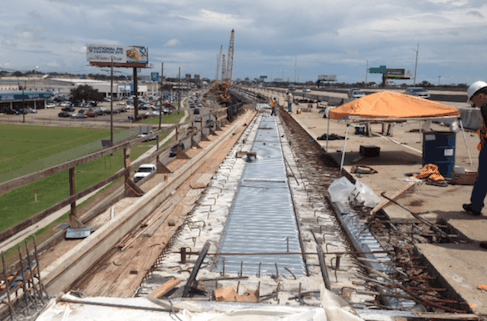

The Bayou Lafourche Bridge is located on US 80 over the Bayou Lafourche Diversion Canal in Louisiana. This project adopted the innovative approach of Accelerated Bridge Construction (ABC) for rapid construction of precast concrete I-girder bridges and marks the first time this process was implemented in Louisiana. This bridge consists of six prestressed concrete girders, supporting the full-depth pre-stressed deck panels. The panels were post-tensioned along the spans during construction. SDR was tasked with instrumentation plan development, installation, and load testing of the bridge in order to study behavior of the bridge at various stages of construction, as well as during service life.

A series of nine load tests were conducted to validate operation of the installed Structural Health Monitoring (SHM) system. Measurement of the bridge’s response to these loading tests created a benchmark for future evaluation of the bridge’s long-term performance.