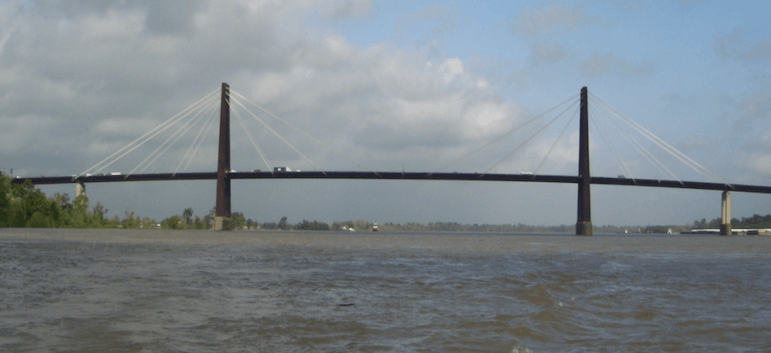

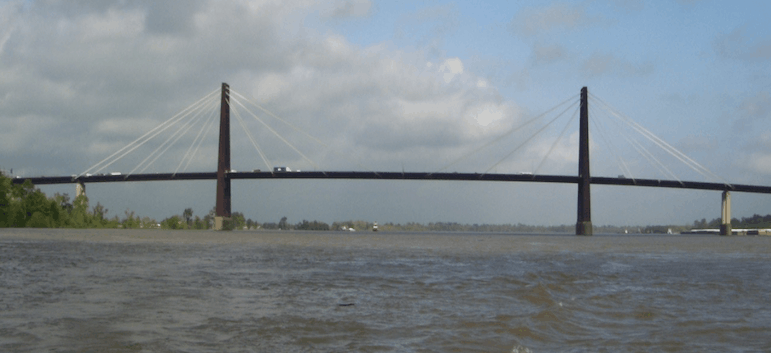

LULING BRIDGE (HALE BOGGS MEMORIAL BRIDGE)

This bridge is a five-span cable-stayed bridge supported by twin steel towers and four concrete piers. The concrete deck overlay is supported by an orthotropic deck system integrated with transverse floor beams supported by twin longitudinal trapezoidal steel box girders. The supporting cables originate from the steel towers and are anchored at twelve transverse steel trapezoidal cross girders. Twin longitudinal trapezoidal steel box girders are supported by these cross girders, towers, and piers.

The scope of work included:

- Detailed inspection of the bridge’s condition, including existing fatigue prone details, and the extent of existing cracks.

- Evaluate and rate the existing bridge superstructure, including all major load-carrying components and bearing seats.

- Investigate the cause of fatigue cracks using 3-D finite element analysis.

- Prepare the bridge rehabilitation design.

- Develop appropriate construction staging/phasing schemes and Maintenance & Protection of Traffic Plan based on TMP Level IV.

- Prepare construction cost estimates and schedule.

Previous

Next