US 71 Market Street

US 71 Market Street

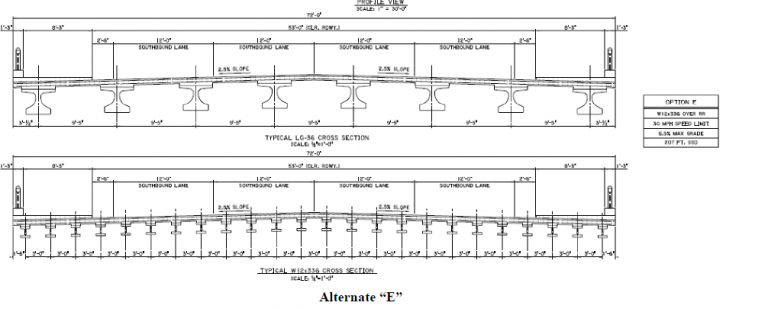

US 71-LA 1 bridge over ICG railroad was built in 1940 in downtown Shreveport, LA. Consisting of a two-bridge structure, each having 15 steel beam spans, 7 reinforced concrete spans, and reinforced concrete approach spans. The bridge covers a length of 850’ and a width of 20’. The US 71-LA 1 bridge carries or crosses multiple modes of transportation, while providing two 5’-11 ½” sidewalks and crossing two railroad tracks.

LA DOTD had posted the bridge for a speed limit of 25 MPH and posted load limits of 20T-35T. Based on further concerns LA DOTD assigned SDR with the task of performing a feasibility study on the twin two-lane bridge. SDR performed a thorough document review, hands-on inspection, and surveying to assess the conditions of the bridge. SDR field inspections indicated that the physical condition of the structure ranged from “fair” to “critical,” depending on their location.

Based on the structure’s old age, displacement, and severe exiting conditions, SDR proposed replacement of both structures and provided two alternate designs. One alternative utilized precast-prestressed concrete to satisfy the railroad’s minimum vertical and horizontal clearance. A second proposed alternative utilized a combination of precast-prestressed concrete girders and heavy, shallow rolled beams to meet railroad clearances. In both cases, span lengths from 80’ to 90’ were recommended to achieve maximum efficiency and to avoid interference with existing bridge foundations.

US-90 MACARTHUR DRIVE INTERCHANGE PHASE Phase II

US-90 MACARTHUR DRIVE INTERCHANGE PHASE II

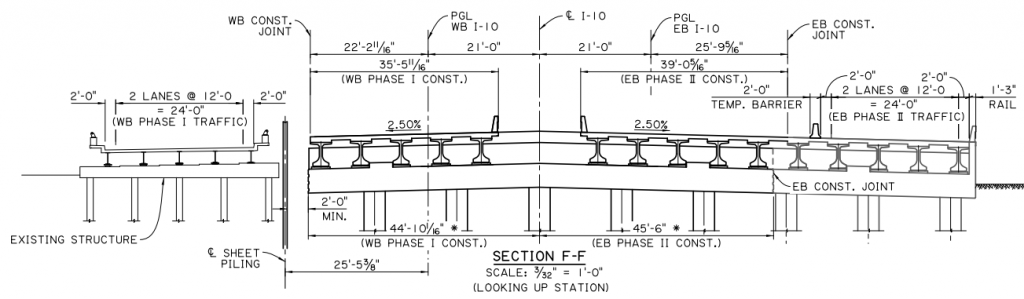

Constructed in the late 1950s, the Westbank Expressway is a six-lane urban, divided and elevated freeway. The elevated section extends from Westwood Drive in Marrero, Louisiana, to the Crescent City Connection Bridge across the Mississippi River, connecting the Westbank communities of Jefferson Parish with downtown New Orleans, Louisiana. Each structure of the elevated expressway includes three 12’ travel lanes, a 6’ interior shoulder, and a 10’ exterior shoulder. The bridges consist of trapezoidal concrete girders supporting a 7½”-thick concrete slab. The superstructure is supported on concrete single pier columns with pile-supported footings. The elevated freeway is supplemented by a six-lane divided service road system at ground level, running parallel to and outside of the twin elevated bridge structures, with ramp connections to major arterial cross streets at intervals of 0.7 to 0.9 miles throughout its length of nearly six miles.

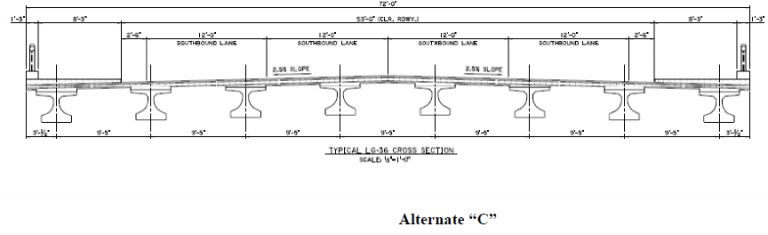

SDR was tasked with providing access ramps from the service roads to the elevated freeway to and from the east and to reduce the distance between successive westbound off-ramps and eastbound on-ramps. SDR designed 22-spans of off-ramp and 24-spans of on-ramp. The design consisted of complex structural elements: precast-prestressed LU-girders and LG-girders, inverted T-cap beams, complex columns, and foundations. SDR also provided precise construction sequence, instructing the removal of existing structures to accommodate the new structure.

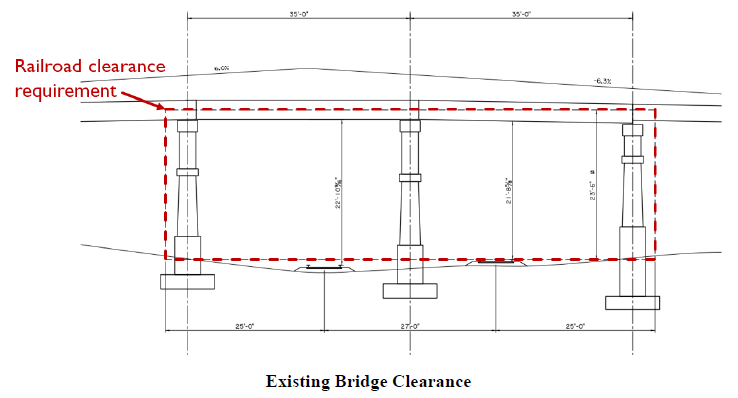

LA-66 BIG BAYOU SARA BRIDGE

LA-66 BIG BAYOU SARA BRIDGE

Big Bayou Sara Bridge is an historic bridge (built in 1949) carrying LA-66 over Big Bayou Sara in West Feliciana Parish, Louisiana. The bridge main spans comprises five, 100 ft. steel pony trusses and the approach spans comprises five, 40 ft. steel I-beam spans with a total bridge length of 700 ft.

Services provided by SDR included in-depth inspection of the superstructure and substructure of the bridge, development of 3-D finite element models to determine internal forces, evaluation of the existing structure to determine deficient elements, design of a rehabilitation system for the superstructure and substructure, development of preliminary and final plans for construction, design of two-lane detour temporary steel bridge to be constructed on the north side of the existing bridge to maintain traffic during rehabilitation work on the existing bridge, development of cost estimation and schedule, and construction support.

LA-1 OVER I-49

LA-1 OVER I-49

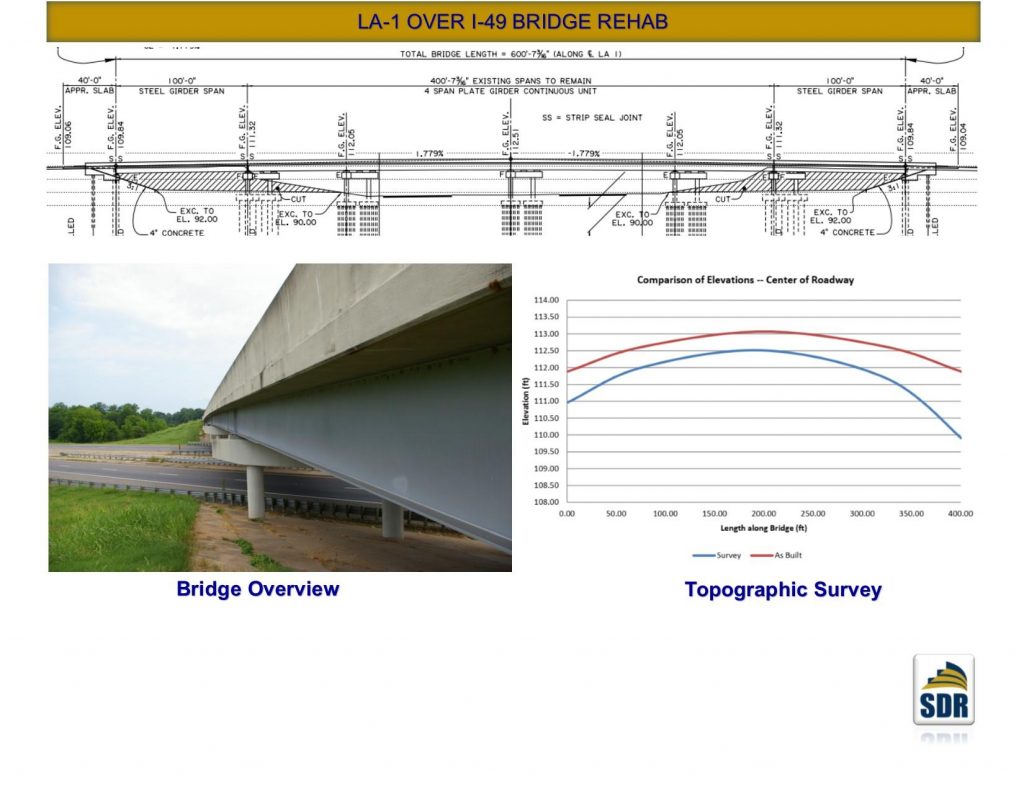

LA-1 over I-49 bridge was built in 1989. The 403 ft. as-built bridge consists of four continuous, steel plate girder spans at 45 degrees skew.

SDR performed thorough document review, hands-on inspection, surveying, and detailed analysis. A topographic survey revealed that both abutments are experiencing excessive settlement and lateral movement resulting in transverse shear and uplift forces on the bearings at both abutments; increased reactions at intermediate bents, causing over-stress and excessive deformation of bearing pads; redistribution of loads to internal supports, which exerts more force on the foundations of internal bents; and additional negative moment, causing high tensile stresses and significant cracking of the deck.

SDR presented three alternatives to rehabilitate the bridge. The selected alternative consisted of adding two end spans of 100 ft. each to reduce the embankment height, and utilizing wraparound Mechanically Stabilized Earth (MSE) walls. In addition, SDR provided construction support.

I-10 OVERPASS OVER US 165

I-10 Overpass Over US 165

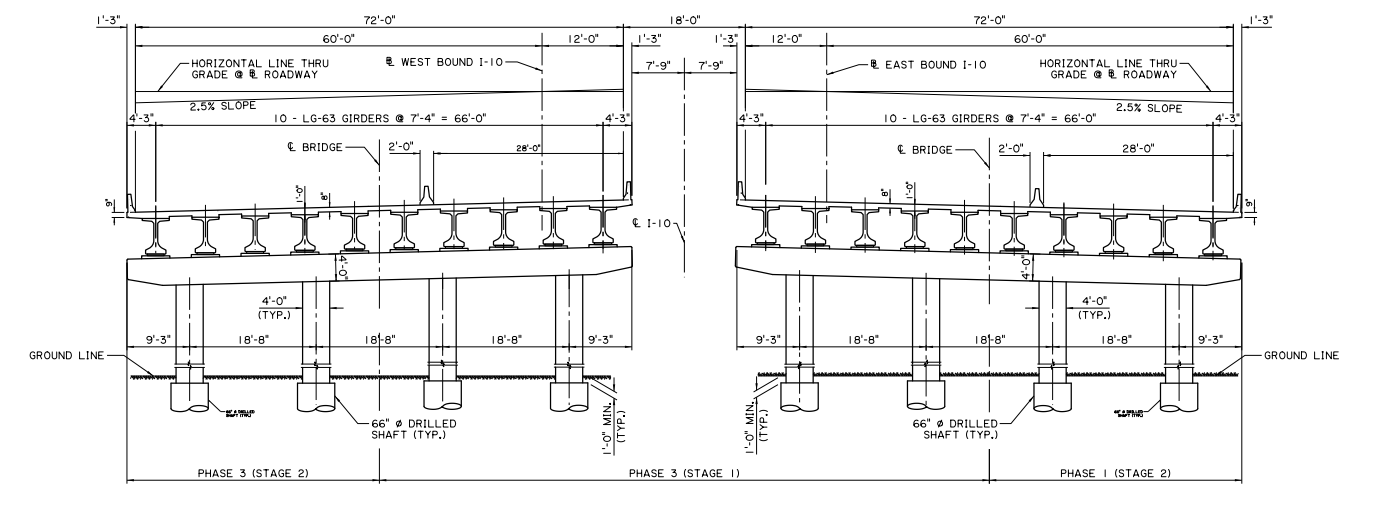

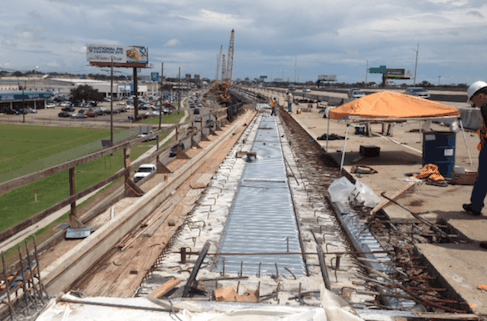

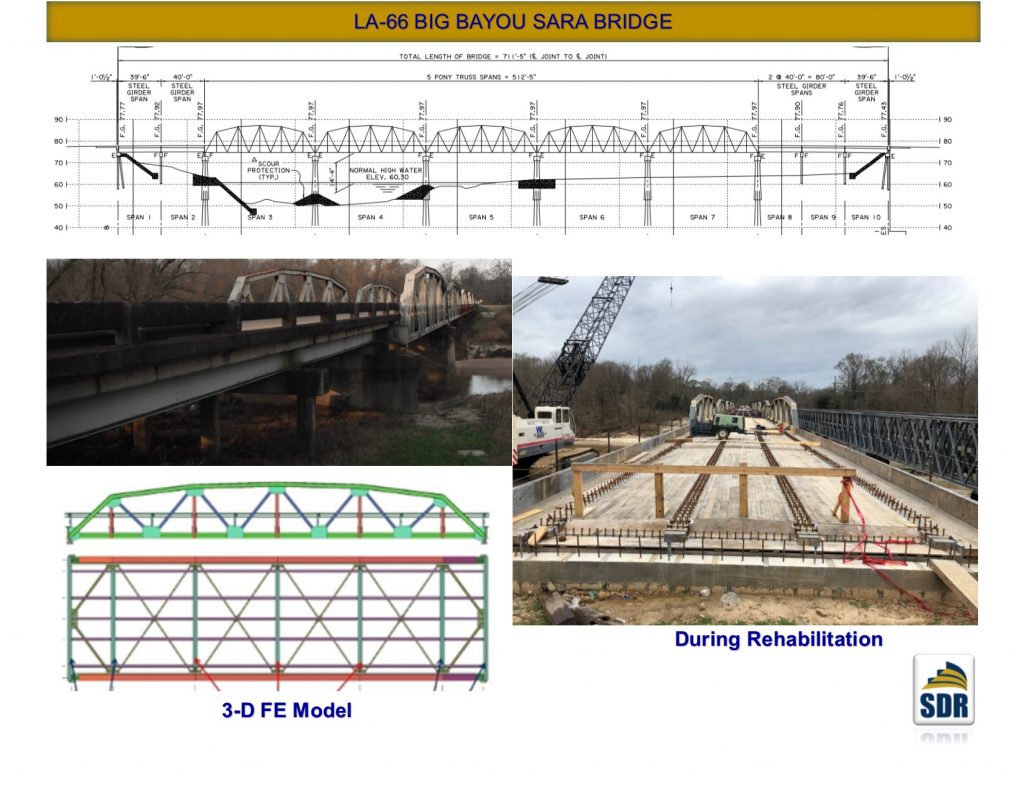

On behalf of the LA DOTD, SDR was tasked with design of the high-traffic volume I-10 overpass, spanning 1,136 ft. and intersecting US 165. The criteria of the project required designing a bridge to withstand immense traffic demand, allowing for future widening as the traffic volume steadily increases over time and conforming with the existing infrastructure surrounding the overpass. The ten-span bridge consists of both 54 in. deep and 63 in. deep prestressed Louisiana I-shaped girders (LG-54 & LG-63), spaced 7.6 ft. and 9.7 ft apart, respectively. The exterior girders were designed with the non-composite section capacity equal to that of the interior girders to facilitate future widening of the bridge to grow with the increase of average daily traffic (ADT), facilitating the longevity of the structure. The bridge is designed to carry four lanes of traffic at design speeds of 70 miles per hour. The overpass incorporates optimum vertical clearance for both the arterial US 165 highway and the railroad it intersects. The bridge design also incorporates aesthetically-pleasing design cues in the implementation of ornamental bridge fencing and functionally sound, decorative bridge parapets.

LA-10 BEAVER CREEK BRIDGE

LA-10 Beaver Creek Bridge

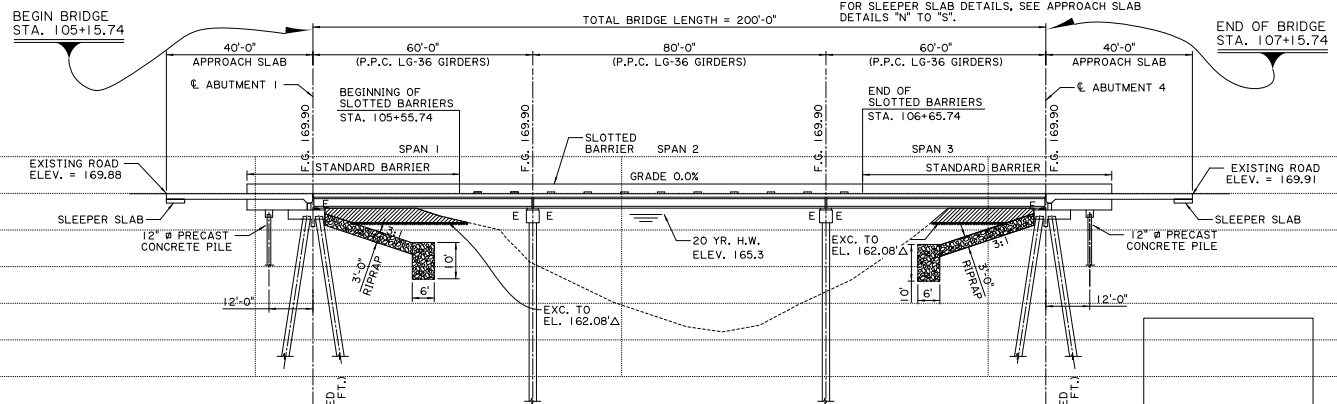

SDR was tasked with emergency design for the replacement of a three-span prestressed concrete bridge that experienced irreparable damage due to flooding. The scope of the LA 10 over Beaver Creek bridge project, designed in just under two months, included finalized plans, cost estimation, surveying, load rating, and the submittal of comprehensive calculations books. The urgency of the project to restore the viability of the LA 10 corridor was met with sound engineering design and was submitted in a timely manner by the SDR team.

The newly-designed bridge has a total length of 200 ft. and a clear roadway width of 40 ft., an increase in width from the pre-existing bridge. The superstructure consists of six 36 in. deep Louisiana I-shaped girders (LG-36), acting in composite action with the 8.5 in. continuous concrete deck. The substructure consists of cast-in-place concrete caps and precast concrete piles. The bridge has an expected 40-plus-year lifespan to service the St. Helena Parish of Louisiana.

MACARTHUR INTERCHANGE US-90 BUSINESS PHASE I

MACARTHUR INTERCHANGE US-90 BUSINESS PHASE I

Full evaluation of the completed bridge widening was carried out under a task for peer review, where several constructability and detailing issues were discovered. SDR performed a full 3-D finite element analysis of the existing bridge, including the inverted-T piers, as well as a bridge load test. After further evaluation it was determined that the widening plans were deficient and re-design was required. SDR was tasked with the design and production of final plans of all superstructure elements, including the prestressed U girders and LG girders, deck, inverted-T caps and columns, and all complex columns with unbalanced loads. In addition, due to the structural complexity of the existing inverted-T piers, SDR performed a special analysis to evaluate and determine the cut lines for accommodating the widening. The evaluation of existing cut lines was performed and new alignment was developed.