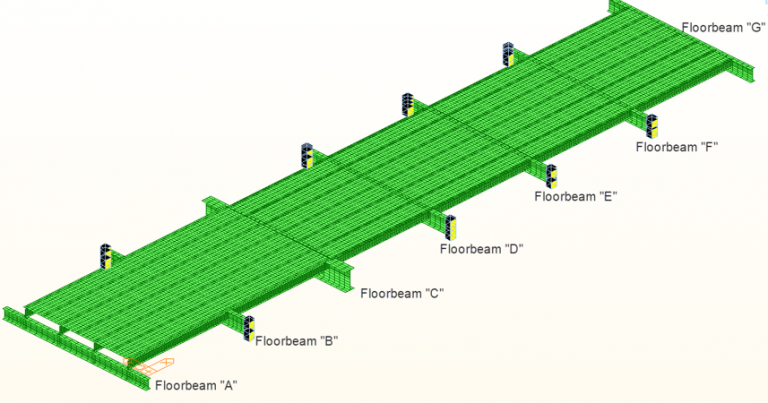

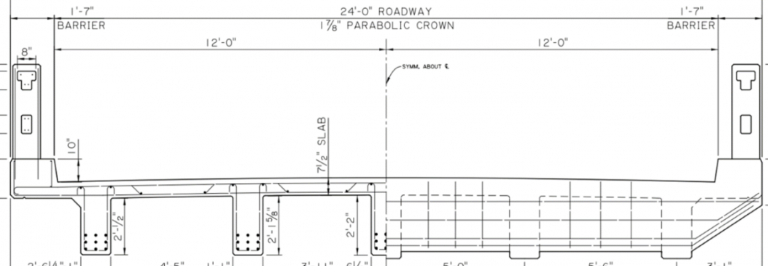

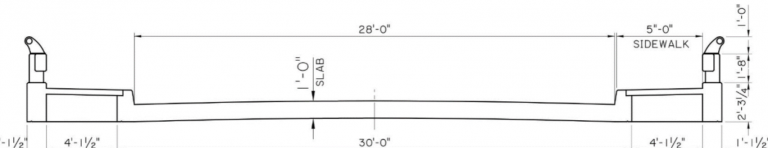

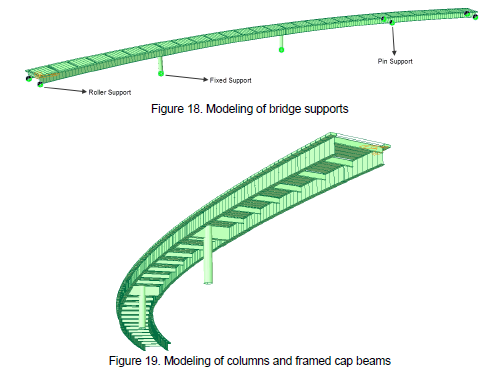

US-61 ramp K over I-10 is located in Ascension Parish, LA. The curved ramp consists of five spans with a total length of 594 ft. The first four spans are continuous steel spans and the last span is a simple composite steel span. The bridge cross section consists of two built-up steel plate girders. The two steel girders support a concrete deck, which is also supported by floor beams that connect the two steel girders.

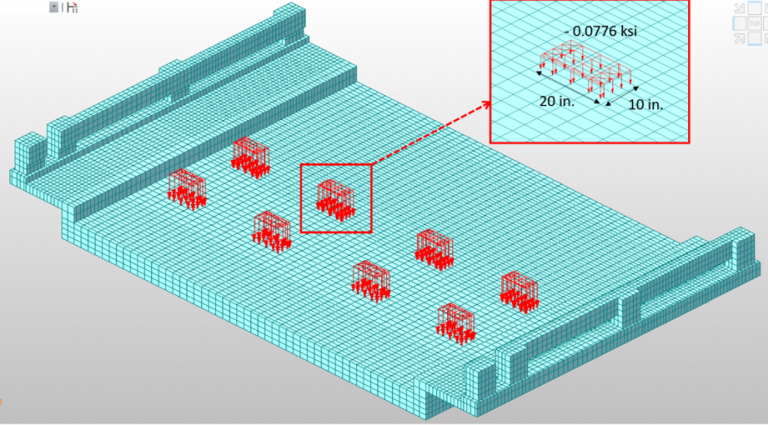

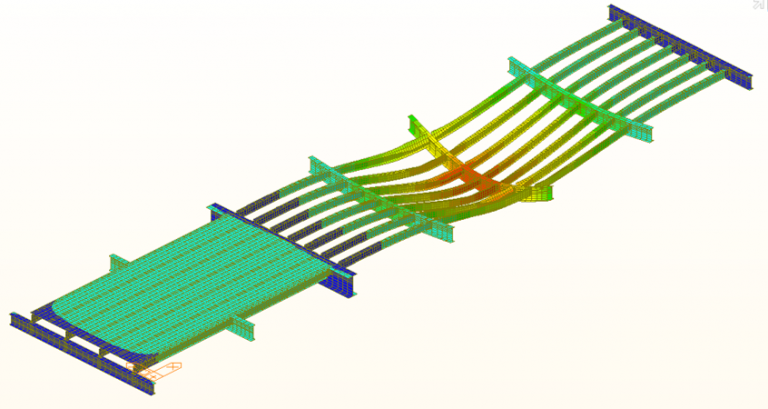

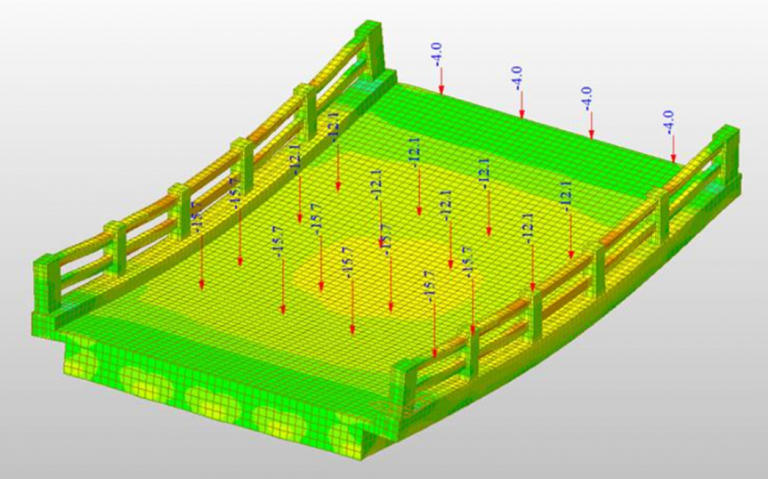

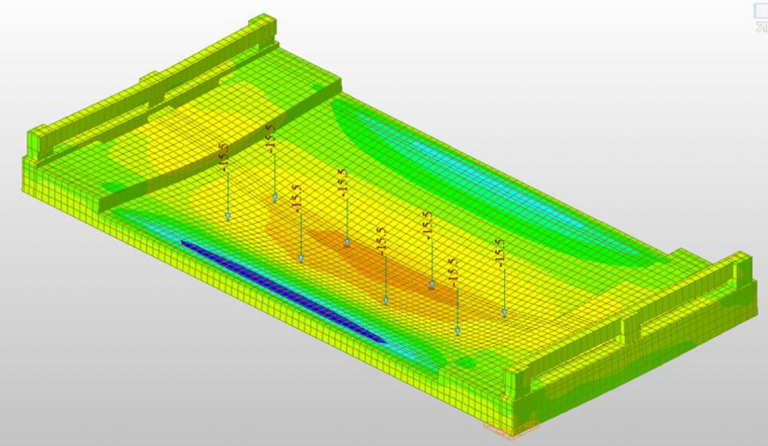

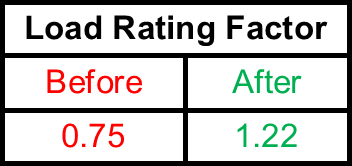

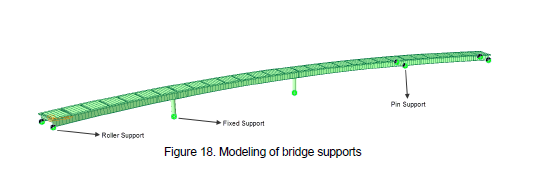

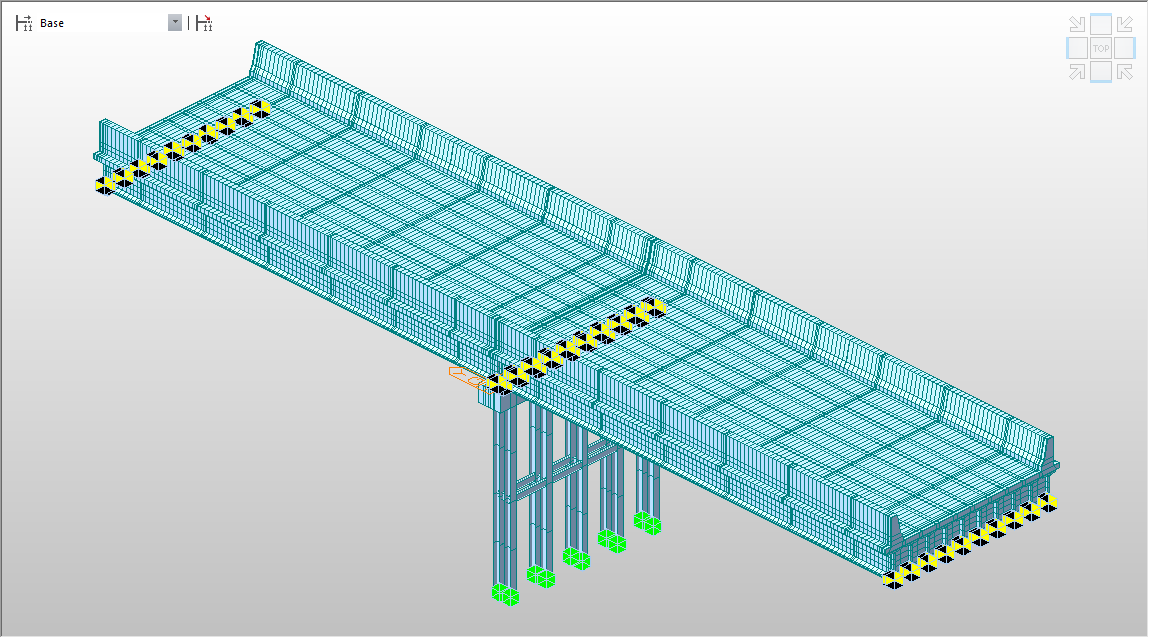

Span 2 of the bridge ramp was struck by an over-height vehicle that was traveling eastbound on I-10, causing damage between the two field splices. SDR was tasked with proposing a practical, safe, and cost-effective solution for the rehabilitation of girder B of the US-61 bridge. SDR performed field inspection of ramp K to identify any distress in the structural elements. In addition to field inspections, SDR developed refined 3-D and 2-D finite element models, based on as-built super structure drawings. Grillage models were used for the main girders and deck. FE analysis accounted for the current condition of the different structural elements as revealed by the field investigation.

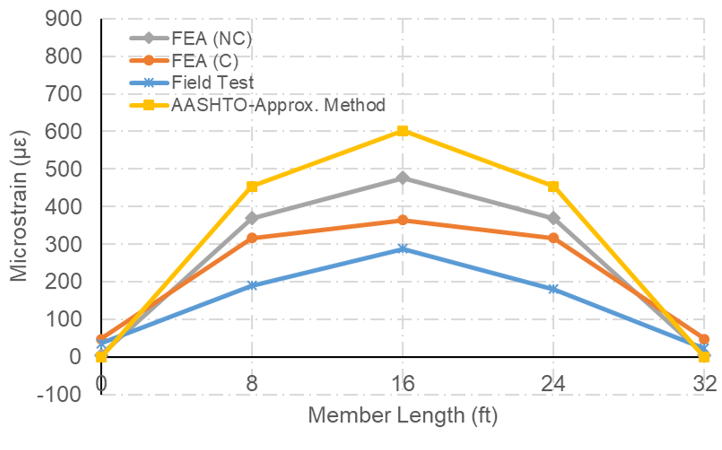

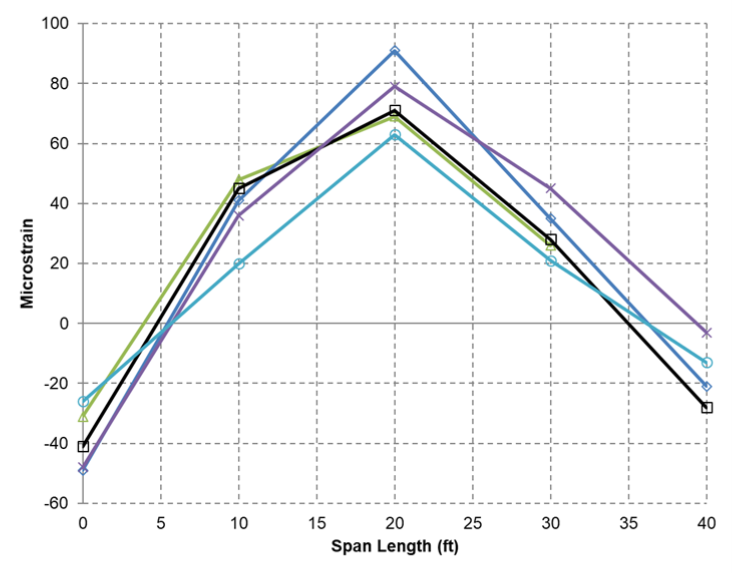

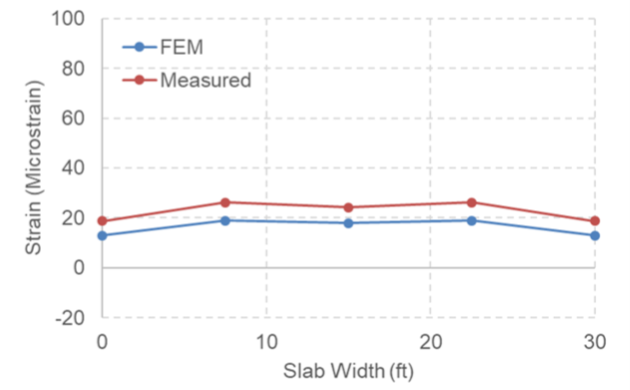

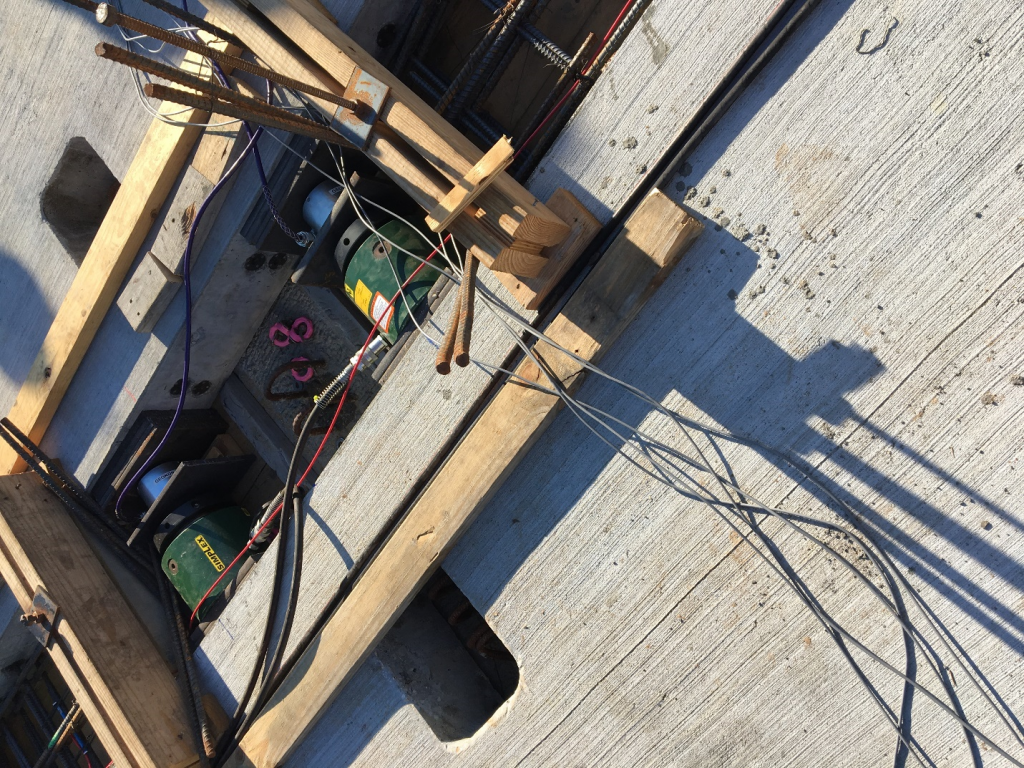

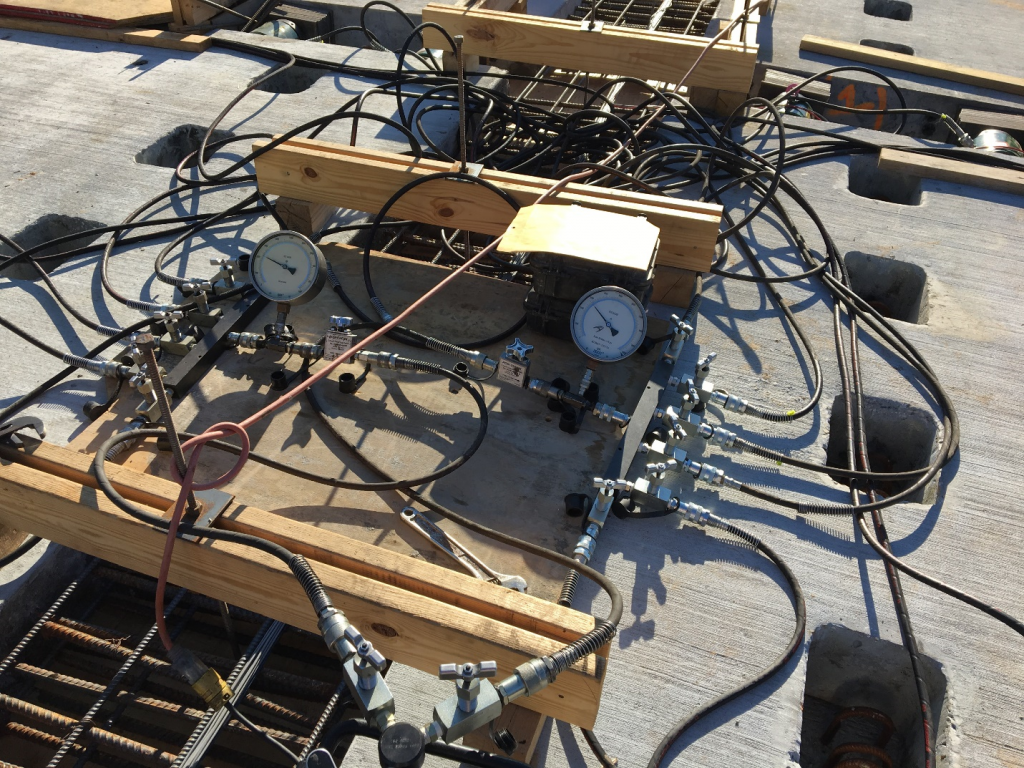

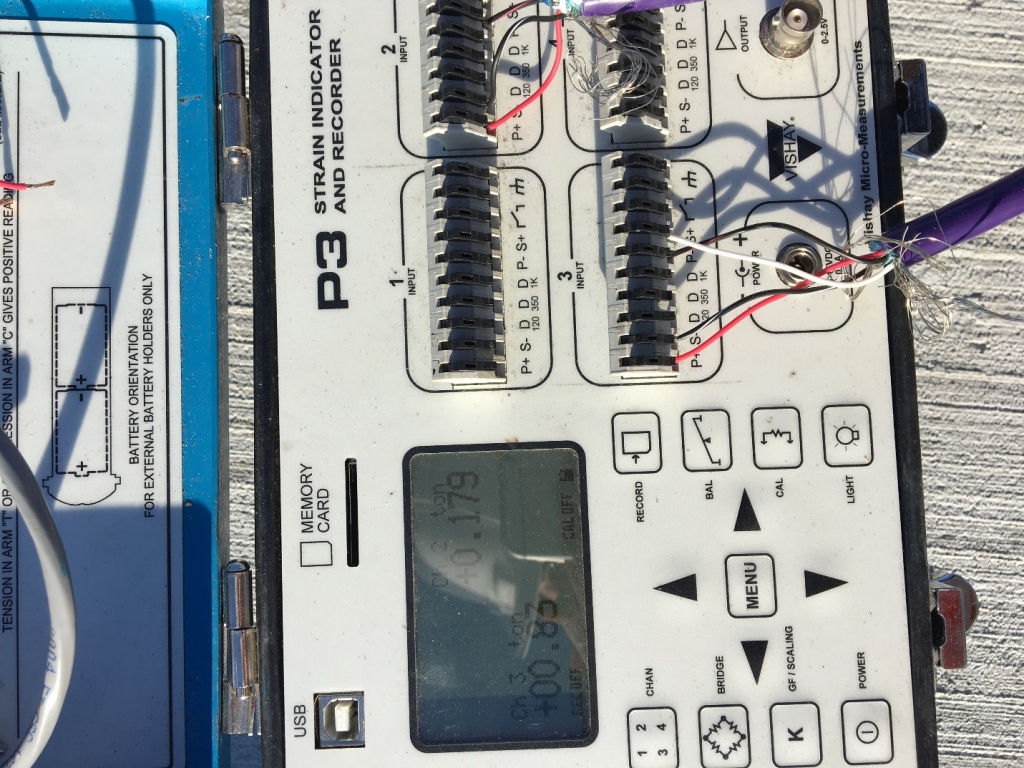

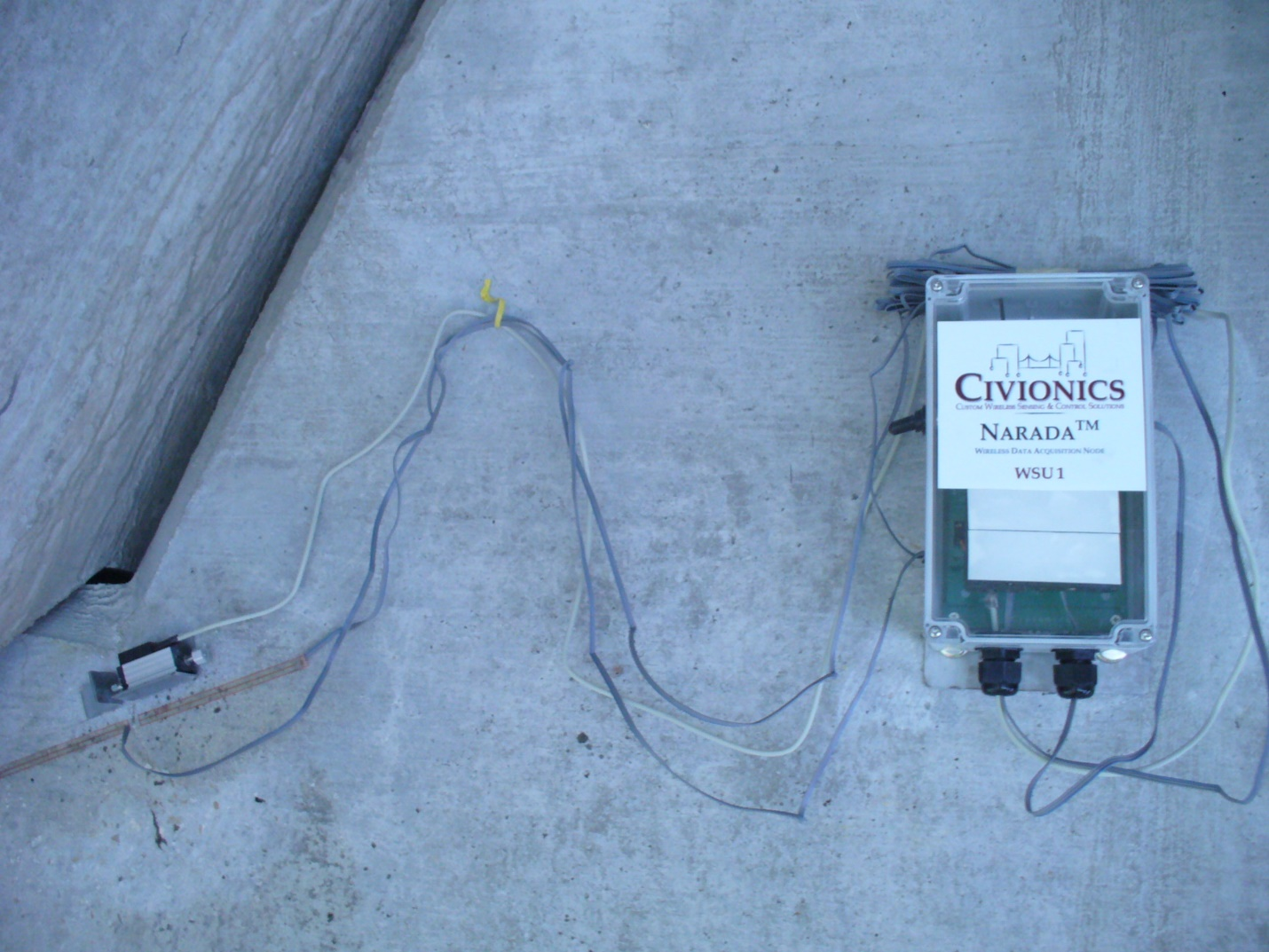

In addition to modeling and field inspections, SDR performed structural evaluation through load testing. Sensors were installed at 6 locations along the length of girder A. Four vibration strain sensors were installed at different positions of the girder A cross section. Five independent truck positions were used to conduct the test.

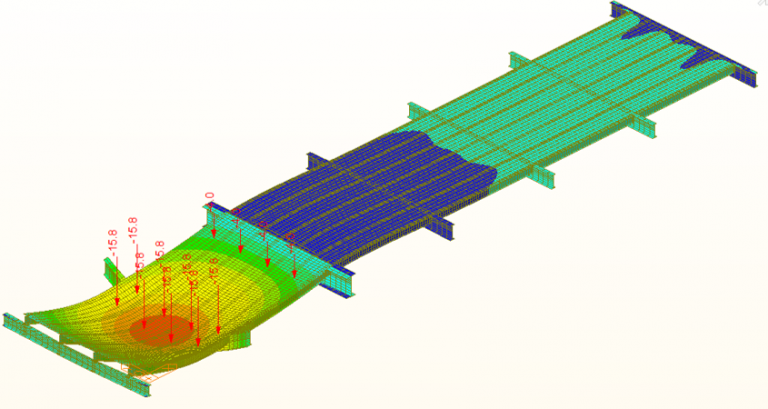

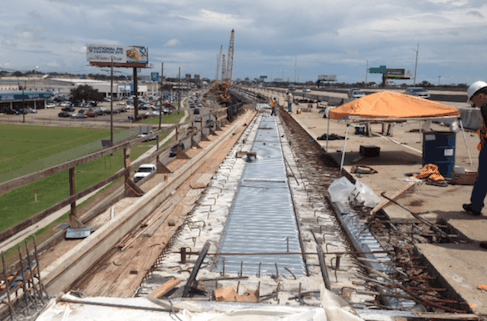

SDR proposed total removal of the concrete deck within the damage segment of the bridge in addition to removal of the concrete deck between the field splices before replacing the damaged portion of the girder. SDR used Midas to model bridge conditions after removal of damaged girder between the two splices. Further, staged construction analysis was performed with FE models to assess the bridge condition during construction. Analysis showed that removal of the damaged portion of the girder and the concrete deck would not cause any structural damage; however, removal did present challenges in construction. Details for laying out the removal and replacement procedures were provided by SDR.

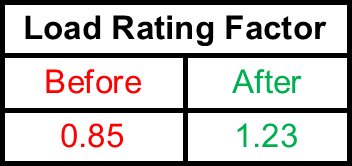

After installation of the span, SDR performed additional structural evaluation through load testing to compare conditions before and after removal of the damaged girder; the load testing was performed with identical sensor locations and truck positioning as compared to testing performed before removal. Stresses and strains were monitored in both evaluations to compare the change in behavior of the new girder.